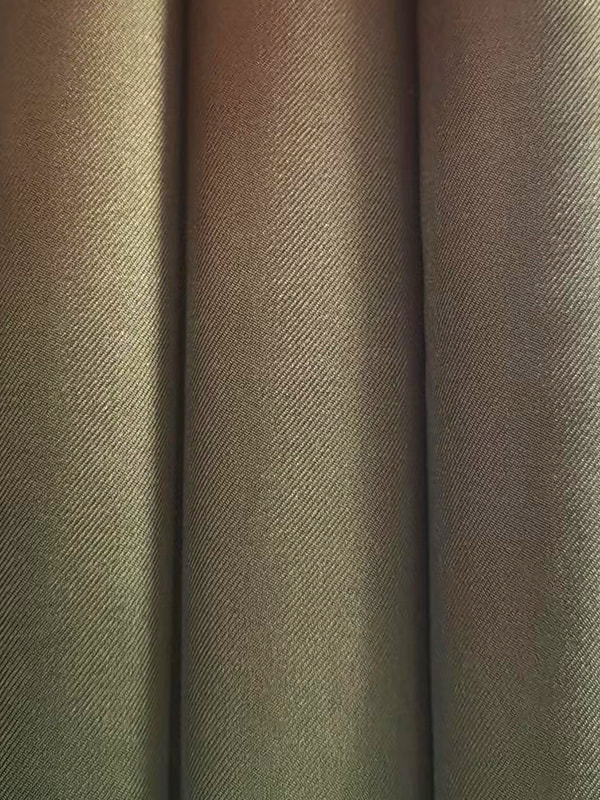

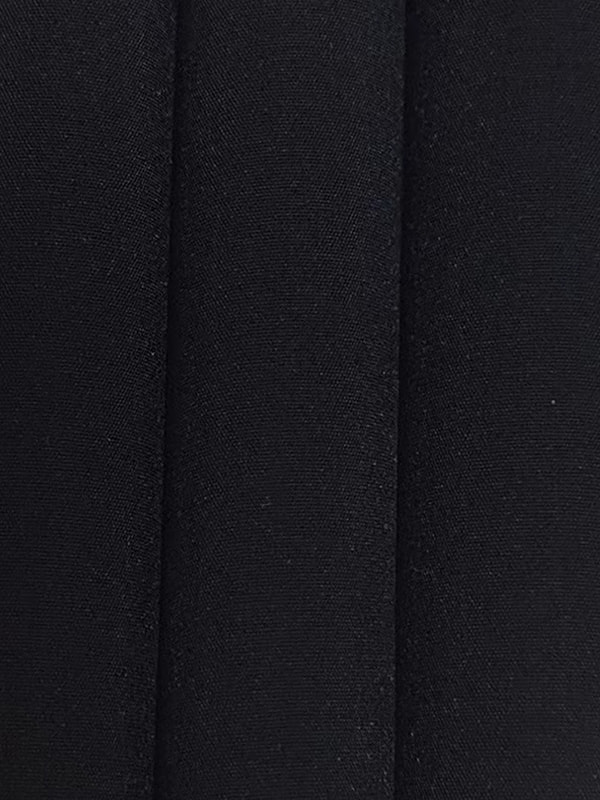

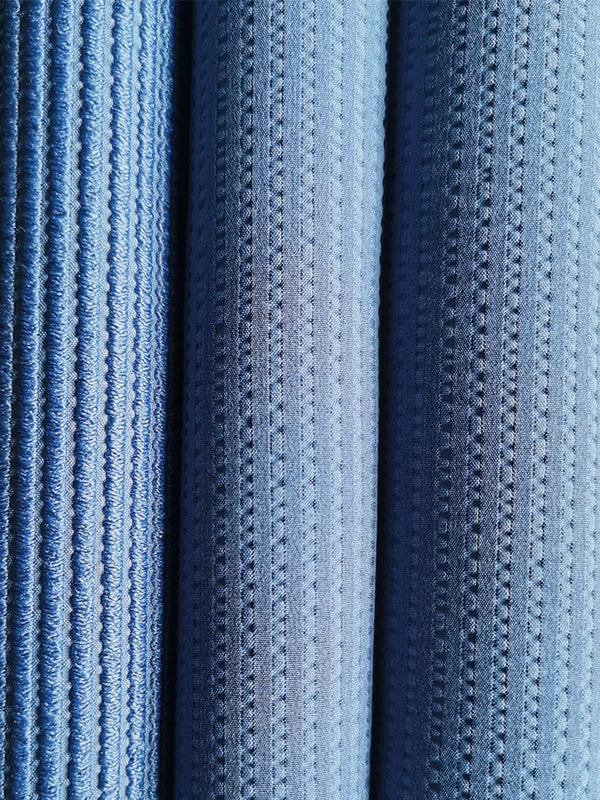

Cationic Polyester T400 Stretch Hole Fabric: Perfect Combination of Elasticity and Breathability

2025-07-10

The core of the high elasticity performance of cationic polyester T400 stretch hole fabric comes from the unique two-component structure of T400 fiber. T400 fiber is composed of polyethylene terephthalate and poly (1,3-trimethylene terephthalate), and the two polyester components constitute the cortex and core of the fiber respectively. PET has high rigidity and strength, while PTT is known for its good flexibility and elasticity. The difference in physical properties between the two is the key to giving the fiber elasticity. During the spinning process, due to the different shrinkage rates of PET and PTT, the cortex and core layers generate internal stress when cooling and solidifying, which causes the fiber to curl naturally to form a spiral structure. This microscopic morphology is just like countless closely arranged micro springs, which lays a solid structural foundation for the high elasticity performance of cationic polyester T400 stretch hole fabric.

Dynamic mechanism of elasticity

When cationic polyester T400 stretch hole fabric is subjected to external force, the bicomponent structure of T400 fiber begins to exert its elastic properties. When the external force stretches the fabric, the spirally curled "spring" structure inside the fiber gradually stretches, and the PET and PTT molecular chains are stretched. At this time, the fiber stores elastic potential energy. This stretching process is not unlimited extension. The cortex and core layer in the bicomponent structure restrain each other to ensure that the fiber deforms within the elastic limit and avoids structural damage caused by excessive stretching. When the external force disappears, the low glass transition temperature of PTT enables it to shrink quickly. With the flexibility and internal stress of its own molecular chain, it drives the fiber to restore its initial spiral curling state. The rigidity of PET helps to maintain the stability of the fiber structure. Under the synergistic effect of the two, the fiber rebounds quickly, so that the fabric as a whole returns to its original state.

Excellent performance of elasticity

Compared with ordinary stretch fabrics, the bicomponent structure of T400 fiber gives cationic polyester T400 stretch hole fabric more elastic performance. The long-lasting elastic recovery rate makes it difficult to relax and deform after frequent stretching. Even after multiple wearing and washing, the made clothes can still fit the body shape and maintain a good version; the stable elastic properties ensure that the performance of the fabric fluctuates little under different temperature environments, whether it is cold winter or hot summer, it can maintain consistent elastic performance; the moderate elastic strength can not only meet the stretching needs of daily activities of the human body, but also provide flexible support for large-scale limb movements during exercise, bringing a comfortable and unrestrained wearing experience in clothing applications.

The value of high elasticity

Cationic polyester T400 Stretch hole fabric has shown unique value in many fields due to the high elasticity brought by the bi-component structure of T400 fiber. In the field of sportswear, when making sports tights and fitness pants, high elasticity can fit the muscle lines closely, reduce air resistance during exercise, provide moderate support for muscles during exercise, and reduce the risk of sports injuries; after exercise, the fabric's rapid rebound characteristics allow the clothes to quickly return to their original state, avoiding loose deformation caused by long-term wear. In terms of household items, when used to make sofa covers and cushion covers, the elasticity enables them to easily adapt to furniture of different sizes, and they are easy to install and not easy to shift. At the same time, in daily use, they can quickly return to flatness and maintain a good appearance in the face of frequent squeezing and sitting.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English 中文简体

中文简体