The Ultimate Guide to Four-Sided Stretch Fabric: Versatility and Performance

2025-10-09

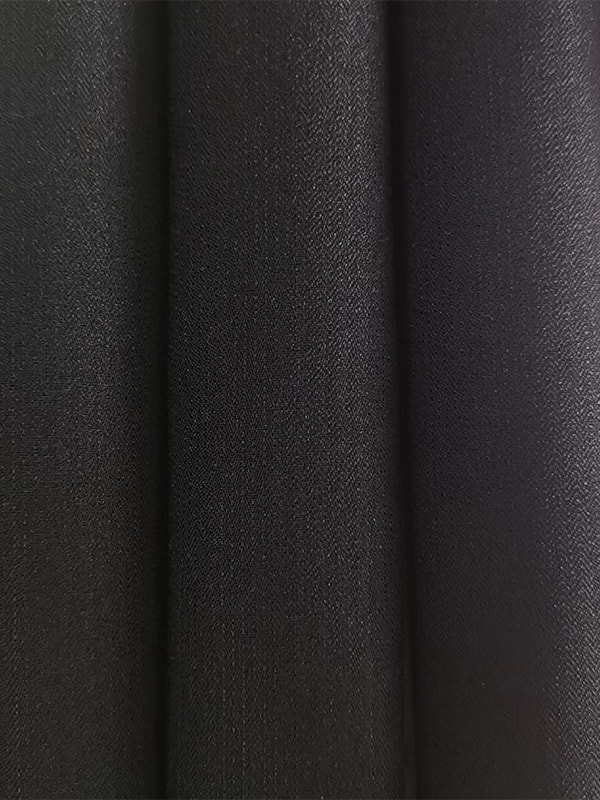

Understanding the Core of Four-Way Stretch Technology

At the heart of modern technical and performance textiles lies a remarkable innovation: four-sided stretch fabric. Unlike traditional materials that offer limited flexibility, this fabric is engineered to stretch and recover in all four directions – north, south, east, and west. This fundamental characteristic unlocks a new dimension of comfort, freedom of movement, and functional application. The technology behind it involves specialized knitting or weaving techniques and the integration of elastic fibers like spandex or elastane into the core construction, creating a matrix that moves dynamically with the body. This makes it an indispensable material across numerous industries, from high-fashion to high-performance athletic wear and beyond.

The Engineering Behind the Stretch

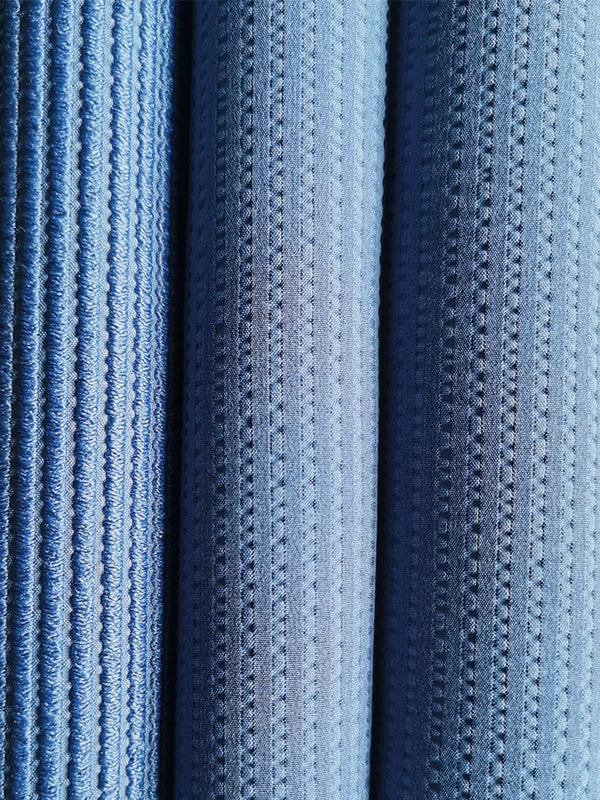

The magic of four-sided stretch fabric isn't accidental; it's a product of precise textile engineering. Most commonly, these fabrics are created using either a circular knit or warp knit method, such as with double-knit machines. These machines can interlock yarns in a way that creates a stable yet incredibly flexible grid-like structure. The key component is the use of high-quality elastomeric yarns. These yarns are often wrapped with other fibers like polyester, nylon, or cotton, which allows designers to imbue the final fabric with additional properties such as moisture-wicking, breathability, or softness, while the core provides the consistent, powerful stretch. The tension and gauge of the knit are meticulously controlled to determine the fabric's weight, compression level, and ultimate stretch potential, ensuring it meets the specific demands of its end use.

Why Four-Way Stretch Outperforms Two-Way Stretch

To truly appreciate the value of four-sided stretch fabric, it is essential to compare it to its predecessor, two-way stretch. Two-way stretch fabric, typically found in many standard activewear pieces, stretches in a single direction, usually horizontally. While this offers some improvement over non-stretch materials, it still restricts movement to a single plane. In contrast, four-way stretch moves bi-axially, providing a complete 360-degree range of motion. This difference is not merely technical; it is profoundly experiential for the end-user.

For instance, consider a yogar performing a deep lunge. Two-way stretch pants might feel tight across the hips and thighs, constricting the movement. Four-way stretch pants would expand in every direction needed—lengthwise for the forward leg and widthwise for the hips—allowing for a deeper, more comfortable pose without any feeling of restriction or fabric strain. This table summarizes the key differences:

| Feature | Two-Way Stretch Fabric | Four-Way Stretch Fabric |

|---|---|---|

| Direction of Stretch | Stretches in one direction (usually horizontally). | Stretches in all four directions (horizontally and vertically). |

| Range of Motion | Offers limited, linear freedom of movement. | Provides complete, multi-directional freedom of movement. |

| Comfort and Fit | Can feel restrictive during complex movements. | Molds to the body's contours without constriction. |

| Common Applications | Basic leggings, t-shirts, some denim blends. | High-performance sportswear, compression garments, technical outerwear. |

Key Benefits and Applications of Four-Sided Stretch Material

The advantages of this versatile material extend far beyond simple elasticity. Its unique properties solve numerous design and functional challenges, making it the material of choice for applications where performance and comfort are non-negotiable. One of its most lauded benefits is its exceptional ability to provide freedom of movement without sacrificing the integrity of the garment's shape. This means clothing retains its original fit and appearance even after repeated stretching and washing, thanks to excellent recovery properties. Furthermore, the snug, conforming fit eliminates excess fabric bagging or wrinkling, creating a sleek, streamlined silhouette that is both aesthetically pleasing and functionally superior.

Dominance in Active and Athletic Apparel

No sector has embraced four-sided stretch fabric more than the athletic wear industry. For athletes, dancers, and fitness enthusiasts, clothing is not just a covering but a tool that can enhance or hinder performance. This fabric is integral to activities that require a full, unrestricted range of motion. In yoga and pilates, it allows for deep stretches and complex poses. In running and cycling, it reduces muscle fatigue and vibration by providing light compression. For high-intensity interval training (HIIT), it offers durability and breathability during explosive movements. The fabric's moisture-wicking capabilities, often enhanced by blending with polyester or nylon, keep the wearer dry and comfortable by pulling sweat away from the skin to the fabric's surface for evaporation. This combination of stretch, support, and climate management is why it has become the undisputed champion of performance apparel.

Expanding into Everyday Fashion and Specialized Uses

While its roots are in performance, the appeal of four-sided stretch fabric has rapidly permeated mainstream fashion and other specialized fields. Designers are leveraging its comfort and fit to reinvent classic pieces. Jeans, blazers, dresses, and even formal wear are now constructed with this technology, offering a level of comfort previously unavailable in such items. Beyond fashion, the fabric's properties are critical in medical applications, such as in four-sided stretch fabric for compression garments used to manage lymphedema or aid post-surgical recovery. The consistent, all-direction pressure is vital for therapeutic effectiveness. Similarly, the upholstery industry utilizes it for furniture covers that must stretch tautly over complex shapes without tearing or losing elasticity, proving that its utility is virtually limitless.

Critical Considerations for Durable 4-Way Stretch Materials

Selecting a high-quality four-sided stretch fabric requires careful attention to several technical specifications that directly impact its performance and longevity. Not all stretch fabrics are created equal, and understanding these factors is crucial for manufacturers, designers, and informed consumers. The durability of the fabric is paramount, especially for applications that involve rigorous activity or frequent washing. This durability is influenced by the quality of the base yarns, the density of the knit, and the percentage and quality of the elastane used. A higher percentage of elastane generally means greater stretch and recovery, but it must be balanced with other fibers to maintain durability and moisture-management properties.

Weight, Compression, and Breathability Factors

The weight of the fabric, typically measured in GSM (grams per square meter), determines its heft and potential applications. Lightweight fabrics (150-200 GSM) are ideal for base layers and lightweight athleticwear, offering maximum flexibility and breathability. Mid-weight fabrics (250-300 GSM) provide more structure and light compression, suitable for everyday training leggings and tops. Heavyweight fabrics (350+ GSM) offer significant compression and are often used for recovery wear or cold-weather training. Breathability is another critical factor, determined by the construction of the knit and the fibers used. Open-knit patterns or blends with natural fibers like cotton enhance air circulation, while tighter knits with synthetic fibers may prioritize compression and moisture-wicking over breathability. Choosing the right combination of these factors is key to finding a durable 4-way stretch material that fits its intended purpose perfectly.

Selecting the Right Fabric for Your Project

Whether you are designing a new activewear line or choosing fabric for a home sewing project, navigating the options can be daunting. The decision should be guided by the end use of the garment. For high-impact activities that require sweat management, a nylon-spandex or polyester-spandex blend is often the best choice. These synthetic blends are exceptionally durable, offer excellent moisture-wicking, and provide strong recovery. For projects where comfort and softness against the skin are the priority, such as in lounge wear or everyday casual wear, a cotton-spandex or rayon-spandex blend might be more appropriate. These blends offer a softer hand feel and better breathability, though they may not wick moisture or recover as well as their synthetic counterparts.

Understanding Blends and Their Properties

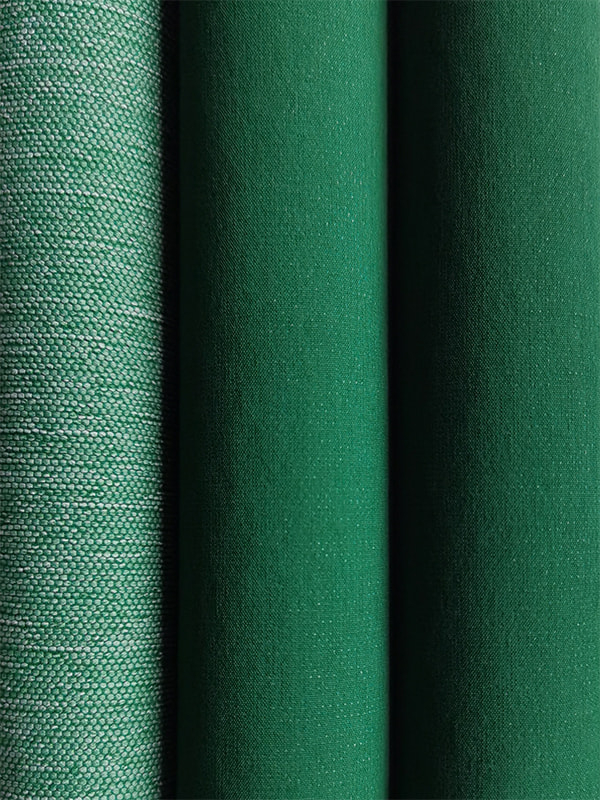

The fiber content blend is the most important determinant of a stretch fabric's behavior. Here is a breakdown of common blends and their characteristics:

- Nylon-Spandex: Known for its exceptional softness, durability, and excellent recovery. It is often used in high-quality swimwear and activewear because of its resistance to chlorine and abrasion. It provides a smooth, compressive feel.

- Polyester-Spandex: Highly durable and resistant to shrinking, stretching, and wrinkles. It is a champion of moisture-wicking, making it a staple for performance shirts, leggings, and sports uniforms. It can be less soft than nylon but is very cost-effective.

- Cotton-Spandex: Prized for its breathability and soft, natural feel. It is incredibly comfortable for daily wear but is less durable and has slower moisture-wicking capabilities than synthetic blends. It is ideal for t-shirts, casual dresses, and lounge pants.

For those seeking a fabric for specific purposes like breathable four-way stretch fabric for summer wear or moisture-wicking 4-way stretch cloth for intense workouts, paying close attention to these blends is the first step to success.

Caring for Your Four-Way Stretch Garments

To preserve the integrity, elasticity, and appearance of four-sided stretch fabric, proper care is essential. The elastic fibers within the fabric are sensitive to heat and harsh chemicals, which can break them down over time, leading to permanent stretching and sagging. The golden rule for caring for these garments is to wash them in cool or lukewarm water on a gentle cycle. Avoid using fabric softeners, as they can coat the fibers and inhibit their moisture-wicking properties and elasticity. Instead, use a mild detergent. When it comes to drying, air-drying is always the safest option. If you must use a dryer, select the lowest heat setting or a tumble-dry without heat to prevent damaging the spandex fibers. By following these simple steps, you can significantly extend the life of your garments and ensure they continue to perform and look their best.

Repair and Long-Term Maintenance

Even with meticulous care, these garments may eventually show signs of wear. Pilling can occur, especially in areas of friction, but can be gently removed with a fabric shaver. For sewing repairs, it's important to use a ballpoint needle and a stretch stitch or a narrow zigzag stitch on your sewing machine to maintain the fabric's elasticity in the sewn seam. Understanding that a comfortable all-direction stretch textile requires specific maintenance will ensure that your investment in quality clothing continues to pay off in comfort and performance for years to come.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English 中文简体

中文简体