Understanding Premium Stretch Fabric: How to Choose, Use and Benefit

2025-11-11

What is Stretch Fabric and why it matters

Definition and key properties of stretch fabric

- Stretch Fabric refers to textile materials that include elastic fibres (such as elastane, spandex) or mechanical constructions allowing extension in one or multiple directions.

- Key properties include elasticity, recovery (ability to return to original shape), drape, durability, and resistance to sagging or bagging.

- These features make it ideal for applications where comfort, movement, and fit are critical.

Why companies like Suzhou Redcolor International Trading Co., Ltd invest in high‑quality stretch fabrics

- The company integrates spinning, texturing, weaving and trade, enabling full control from fibre to finished textile.

- With two production bases (Wujiang, Suzhou and Siyang, Suqian) and an annual output of about 60 million metres of various textiles, the scale supports consistent supply.

- By adhering to the concept of “high‑quality and better products to serve every customer”, the company ensures its stretch fabrics meet international standards for markets in the United States, Europe and Southeast Asia.

How to select the right fabric for your application

Application: activewear → high four way stretch fabric for activewear

- Activewear demands full freedom of movement. A four‑way stretch fabric (stretch in both warp and weft) offers superior mobility.

- Look for good elasticity (e.g., 20‑30 % elongation each direction) and strong recovery for repeated use.

- Ideal for leggings, performance tops, compression garments.

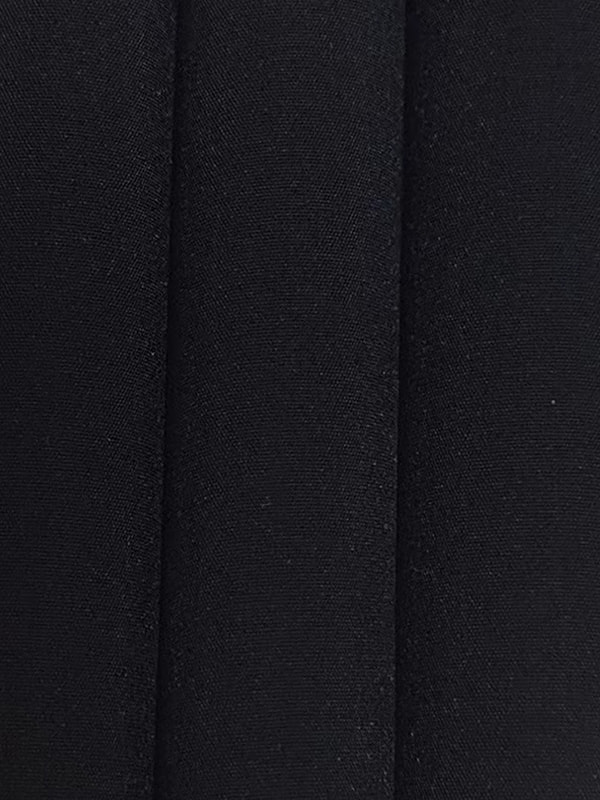

Application: linings → breathable stretch fabric for linings

- Stretch fabrics used for linings must balance elasticity with comfort and air‑flow (breathability).

- They should be lightweight and smooth, with enough stretch to conform but not distort the garment shape.

- Often used inside tailored pieces or outerwear where movement is required but volume must be controlled.

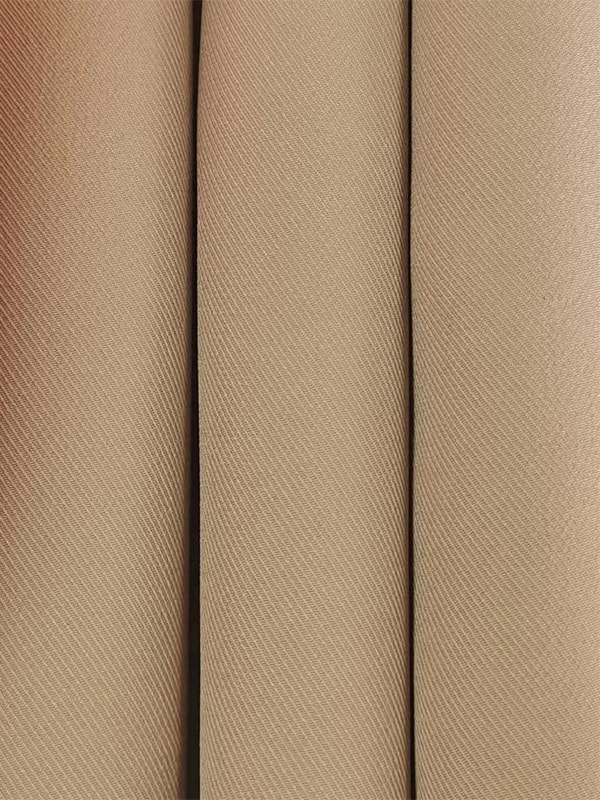

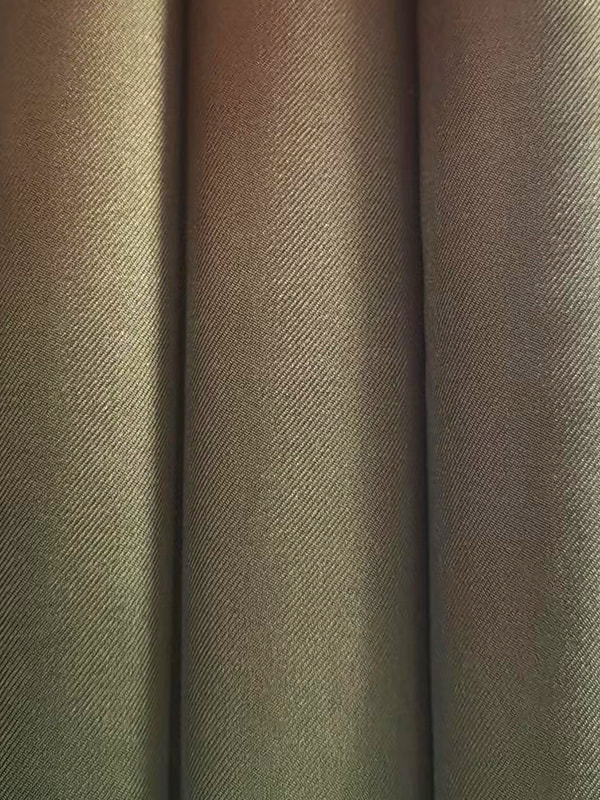

Application: workwear → durable stretch fabric for workwear uniforms

- Workwear environments impose high abrasion, frequent movements, and need for resilience.

- “Durable stretch fabric for workwear uniforms” emphasises strength of weave, good recovery, and resistance to bagging at knees/elbows.

- Suitable for uniforms in manufacturing, security, service industries where comfort + durability matter.

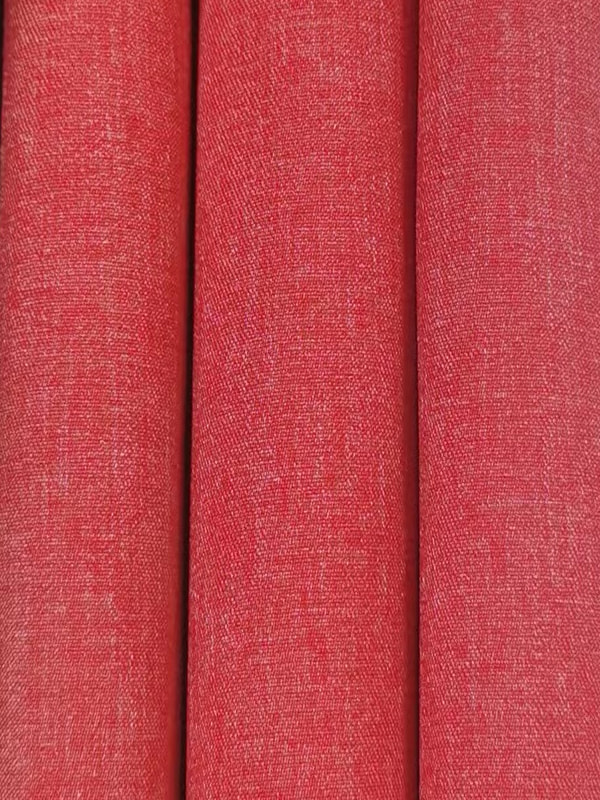

Application: sustainable textiles → eco friendly stretch fabric made from recycled yarn

- As sustainability becomes more important, fabrics labelled “eco friendly stretch fabric made from recycled yarn” appeal to environmentally conscious markets.

- These fabrics use recycled fibres (e.g., recycled PET, regenerated elastane blends) while still providing stretch functionality.

- Important to verify certifications and physical performance to ensure recycled stretch meets same standards.

Application: outerwear shell → water resistant stretch fabric for outer shell garments

- For outerwear shells, fabric must combine stretch with water resistance or repellence.

- Water resistant stretch fabric for outer shell garments is engineered to allow mobility and protection from the elements.

- Often used in jackets, soft‑shells, rainwear where movement + barrier performance are required.

Comparative overview of fabric choices

Two‑way vs four‑way stretch explained

- Two‑way stretch: fabric stretches in one direction (usually weft), better suited for simpler shapes.

- Four‑way stretch: stretches in both warp and weft, offers full mobility especially for form‑fitting garments.

Breathability vs water resistance: trade‑offs in stretch fabrics

- Generally, increased water resistance often reduces breathability because coatings or membranes block air flow.

- Highly breathable fabrics may sacrifice some barrier performance unless specifically engineered.

| Fabric Type | Stretch Direction | Primary Application | Trade‑off |

| High four‑way stretch fabric for activewear | Both warp & weft | Performance leggings, compression wear | May cost more, lower durability than heavy weave |

| Breathable stretch fabric for linings | Typically weft‑bias | Garment linings where comfort is key | Less durable than heavy duty outer fabrics |

| Durable stretch fabric for workwear uniforms | Often warp bias with reinforcement | Workwear, service uniforms | Less drape, heavier feel |

| Eco friendly stretch fabric made from recycled yarn | Depends on construction | Sustainable apparel market | May need verification of performance properties |

| Water resistant stretch fabric for outer shell garments | Often four‑way + coating/membrane | Soft‑shell jackets, rainwear | Breathability may be reduced unless advanced tech used |

Why partner with a full‑scale textile producer

Introducing Suzhou Redcolor and its production capabilities

- Suzhou Redcolor International Trading Co., Ltd. has subsidiaries such as Suzhou LJC Textile Co., Ltd. and Wujiang Jiabaokang Textile Co., Ltd.

- The enterprise integrates spinning, texturing, weaving and trade, enabling end‑to‑end textile production.

- With two production bases in Wujiang (Suzhou) and Siyang (Suqian), the annual output is about 60 million meters of various types of textiles, including shell & lining materials for international and domestic markets (United States, Europe, Southeast Asia).

What this means for reliability, output and global markets

- The vertical integration allows tight quality control from fibre through to finished fabric, reducing risks, improving consistency and innovation potential.

- Large output capacity (≈ 60 million m / year) means better capacity to handle bulk orders, seasonal fluctuations and customised runs.

- Global market servicing (US, Europe, Southeast Asia) demonstrates the fabrics meet international specifications and delivery frameworks.

- For a buyer seeking any of the five specific stretch fabric types above, the company’s scale and full‑chain production offers a strategic sourcing advantage.

Practical tips for specification & sourcing

Key parameters to ask for: % elastane, weft/warp directions, recovery, weight (gsm)

- Check the elastane or stretch fibre content (e.g., 2–10 % elastane) and whether stretch is mechanical or blended.

- Ask for stretch direction data: e.g., “20 % elongation in warp and 30 % in weft after 10,000 cycles.”

- Recovery or “return to original length” is critical for shape‑holding garments.

- Weight (gsm), fabric construction (knit vs woven), and finishing (coatings, membranes) affect end‑use suitability.

- Don’t neglect tests: abrasion, ball‑burst, pilling, colourfastness, and stretch‑recovery cycles.

How to match the right Stretch Fabric variant to your product

- Define your end‑use first: activewear? outer shell? lining? workwear?

- Map your performance priorities (mobility, durability, breathability, water resistance, sustainability). Then select the variant that aligns best.

- Use the table above to compare trade‑offs and guide decision‑making.

- Work with your textile partner (such as Suzhou Redcolor) early to request samples and proof of performance rather than waiting until too late in the design cycle.

Conclusion & next steps

In the competitive textile market, selecting the right Stretch Fabric can make the difference between a garment that performs and one that disappoints. Whether you’re developing activewear, lining materials, uniforms, sustainable apparel or outer‑shell garments, the five long‑tail variations above offer clear, targeted pathways: high four way stretch fabric for activewear, breathable stretch fabric for linings, durable stretch fabric for workwear uniforms, eco friendly stretch fabric made from recycled yarn, and water resistant stretch fabric for outer shell garments. Partnering with a full‑chain producer like Suzhou Redcolor enables access to quality, scale and international reach. Starting with clear specification, sample testing and aligning performance needs will set you up for success.

FAQ

- Q1: What stretch direction is best for a form‑fitting activewear garment?

Answer: For form‑fitting activewear, a four‑way stretch fabric (stretch in both warp and weft) offers the most freedom of movement and recovery. - Q2: How does breathability differ from water resistance in stretch fabrics?

Answer: Breathable fabrics allow air/moisture vapour to pass readily, improving comfort; water resistant fabrics use coatings or membranes that block moisture but may reduce air flow – the trade‑off must be balanced for the intended use. - Q3: Can stretch fabrics be sustainable?

Answer: Yes — you can source an eco friendly stretch fabric made from recycled yarn, but you should verify fibre origins, recycling processes and whether the performance (stretch, recovery, durability) matches non‑recycled equivalents. - Q4: What parameters should I inspect when selecting stretch fabric for workwear?

Answer: Look at durability (abrasion, tearing), elongation and recovery under cycles, weight/gsm, stretch direction, resistance to sagging (knees/elbows) and whether finishes (e.g., anti‑wrinkle) are applied. - Q5: Does using a large‑scale textile producer matter?

Answer: Yes — working with a vertically‑integrated producer (spinning, texturing, weaving, trade) such as Suzhou Redcolor helps ensure consistent supply, quality control, sample testing, and international compliance, all of which reduce risks when selecting the right stretch fabric.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English 中文简体

中文简体