A Comprehensive Guide to Mechanical Stretch Fabric: Technology, Applications, and Selection

2026-02-04

In the dynamic world of modern textiles, performance and comfort are no longer mutually exclusive. At the heart of this innovation lies mechanical stretch fabric, a category engineered to provide freedom of movement, superior fit, and enhanced durability without relying on elastic fibers like spandex. As a textile production enterprise that integrates spinning, texturing, weaving, and trade, Suzhou Redcolor International Trading Co., Ltd. leverages its extensive manufacturing expertise to produce high-quality stretch textiles for global markets. This guide delves deep into the mechanics, benefits, and practical considerations of these versatile fabrics.

What is Mechanical Stretch Fabric and How Does It Work?

Unlike elastane-based stretch fabrics, mechanical stretch achieves its elasticity through a specialized engineering of the yarn and weave structure. The stretch capability is physically built into the fabric's construction.

The Core Mechanisms of Stretch

There are two primary methods for creating mechanical stretch, each offering distinct characteristics.

1. The Yarn Structure Method: Crimping and Coiling

- Process: Yarns are physically textured, crimped, or coiled using advanced mechanical or heat-setting processes.

- Principle: When the fabric is pulled, these coiled yarns straighten, allowing the material to extend. Upon release, they spring back to their original form.

- Common Techniques: False-twist texturing, air-jet texturing, and knit-de-knit processes.

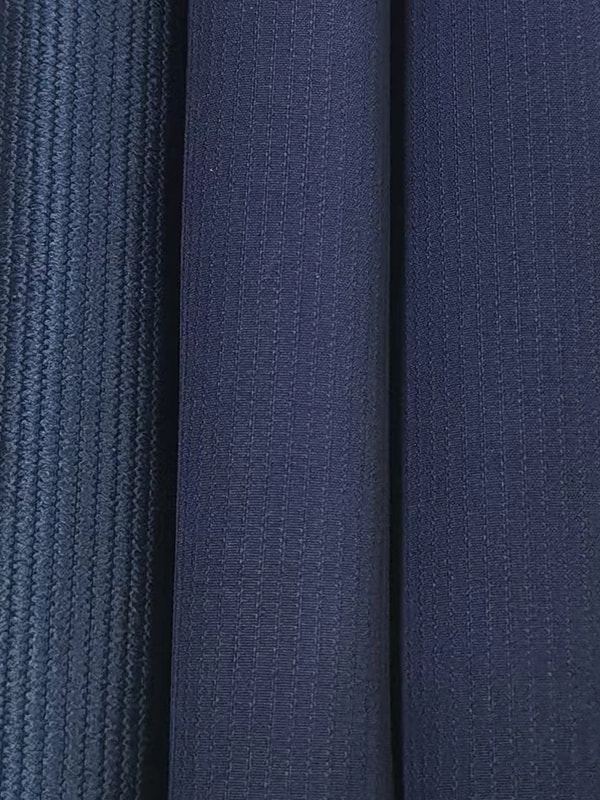

2. The Fabric Structure Method: Weave and Knit Engineering

- Process: Stretch is generated through the specific interlooping of yarns in knitting or a special "stretch weave" like a 2-way or 4-way construction.

- Principle: The loops in a knit fabric can expand and contract. In woven fabrics, a special loom setup allows yarns to slip over each other under tension, creating give.

- Common Constructions: Single jersey knits, double knits, and specific satin or twill weaves with stretch yarns.

Key Advantages of Choosing Mechanical Stretch Fabrics

The unique construction of mechanical stretch fabrics translates into several tangible benefits for both manufacturers and end-users, making them a preferred choice for high stretch woven fabric for workwear and other demanding applications.

Enhanced Durability and Longevity

- Resistance to Degradation: Without synthetic elastomers that can break down with heat, chlorine, or UV exposure, mechanical stretch fabrics often maintain their elasticity and integrity longer.

- Robust Construction: The focus on yarn and weave strength results in a fabric that can withstand repeated stress and abrasion.

Superior Comfort and Fit

- Dynamic Movement: The fabric moves with the body, reducing restriction and improving comfort during activity.

- Improved Drape: Many mechanical stretch fabrics offer a better, more natural drape compared to stiff, non-stretch counterparts.

Functional Versatility

- From athletic wear to formal suits, the adaptability of these fabrics makes them suitable for a wide range of uses where both form and function are critical.

Mechanical Stretch vs. Spandex (Elastane) Stretch: A Detailed Comparison

Choosing between mechanical and chemical stretch is a fundamental decision. The following analysis highlights their key differences. For instance, mechanical stretch is often chosen for applications requiring durable stretch fabric for outdoor apparel due to its environmental resilience.

To provide a clearer comparison, here are the key distinctions:

| Feature | Mechanical Stretch Fabric | Spandex/Elastane Blend Fabric |

| Core Mechanism | Physical yarn/texture or weave structure. | Incorporation of synthetic elastic fibers (e.g., Lycra). |

| Stretch Recovery | Good to excellent, but can relax over time with extreme stress. | Typically excellent and consistent high-power recovery. |

| Durability Factors | High resistance to oils, chlorine, heat, and UV degradation. | Can be degraded by chlorine, heat (high-temp washing), and UV exposure. |

| Comfort & Breathability | Often more breathable and has a natural fabric hand feel. | Can be less breathable; feel depends on the base fabric blend. |

| Common Applications | Workwear, outdoor gear, shirting, suiting, durable knits. | Athletic wear, swimwear, fashion leggings, tight-fitting garments. |

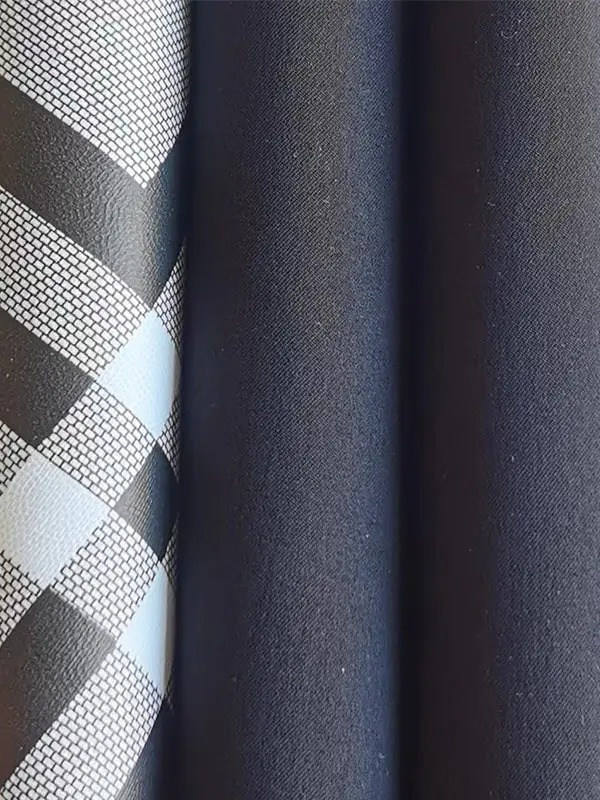

Top Applications of Mechanical Stretch Technology

The utility of mechanical stretch fabrics spans numerous industries. Their reliability is why they are specified for mechanical stretch fabric for automotive interiors, where materials must endure constant use and temperature fluctuations.

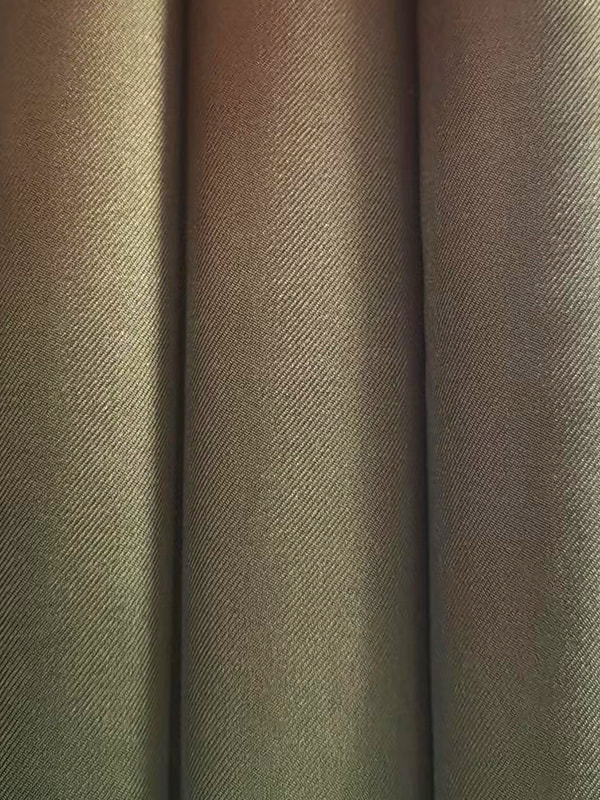

Performance and Outdoor Apparel

- Workwear & Uniforms: Provides mobility for tradespeople without sacrificing fabric strength or professional appearance.

- Outdoor & Adventure Gear: Used in hiking pants, jackets, and equipment where durability against the elements is paramount.

Fashion and Tailoring

- Modern Suiting & Trousers: Offers comfort and maintains a sharp silhouette even when sitting or moving.

- Denim: Many stretch denims use a mechanical method for a more recovery-resistant and durable stretch.

Technical and Industrial Uses

- Automotive Upholstery: Fabrics need to stretch over seats and door panels while resisting wear, sunlight, and heat.

- Medical & Healthcare Textiles: Used in certain supports or uniforms where consistent fit and easy movement are needed.

How to Select the Right Mechanical Stretch Fabric

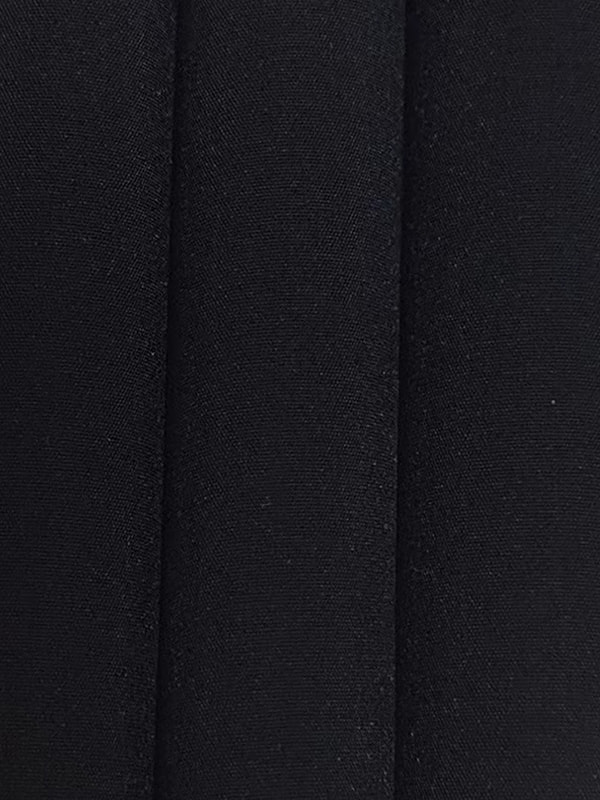

Selecting the appropriate fabric requires careful consideration of the end-use. For projects like breathable mechanical stretch fabric for sportswear, the balance between airflow and recovery is key. Similarly, understanding mechanical stretch fabric cost per meter is crucial for budget-conscious projects without compromising on necessary performance.

Critical Performance Parameters to Evaluate

- Stretch Percentage & Direction: Determine if you need 2-way (warp or weft) or 4-way (bi-directional) stretch and the required elongation percentage.

- Recovery Rate: The fabric's ability to return to its original shape after stretching is critical for garment fit over time.

- Fabric Weight and Composition: Heavier weights offer more durability; fiber composition (polyester, nylon, cotton, wool) affects feel, breathability, and care.

Quality and Compliance Considerations

- Pilling and Abrasion Resistance: Test for Martindale or Wyzenbeek rub counts, especially for upholstery or high-wear areas.

- Colorfastness: Ensure the fabric meets standards for washing, light, and crocking (rubbing) to maintain appearance.

- Compliance Certifications: Look for relevant certifications like OEKO-TEX for safety or specific industry standards.

With production bases in Wujiang and Siyang, and an annual output of approximately 60 million meters, Suzhou Redcolor International Trading Co., Ltd. controls the entire process from spinning to weaving. This vertical integration allows for precise engineering of these parameters, ensuring that every meter of mechanical stretch fabric meets stringent quality and performance targets for markets in the United States, Europe, Southeast Asia, and beyond.

Care and Maintenance for Long-Lasting Performance

Proper care is essential to preserve the stretch, recovery, and appearance of these fabrics.

Best Practices for Washing and Drying

- Follow care labels, but generally, use lukewarm water and mild detergents.

- Avoid high heat in dryers, as it can damage yarn memory and shrinkage. Air drying is often recommended.

- Turn garments inside out to minimize surface abrasion during wash cycles.

Ironing and Storage Tips

- Use a medium iron temperature appropriate for the base fiber (e.g., polyester = low heat).

- Store garments flat or hanging without excessive tension to prevent the fabric from stretching out of shape.

Frequently Asked Questions (FAQ)

1. What is the main difference between mechanical and spandex stretch?

The core difference lies in the source of elasticity. Mechanical stretch is created through the physical structure of the yarn or fabric weave, while spandex stretch relies on the inherent elasticity of synthetic elastomer fibers blended into the fabric.

2. Does mechanical stretch fabric lose its stretch over time?

All stretch fabrics can experience some reduction in recovery with extensive wear and stress. However, high-quality mechanical stretch fabrics are engineered for excellent durability. Their recovery tends to be more resilient to factors like heat and chlorine compared to spandex, but proper care is essential to maximize lifespan.

3. Is mechanical stretch fabric breathable?

Yes, it often is. Since it can be made from 100% natural or non-elastic synthetic fibers (like polyester or nylon) without a rubbery elastomer component, it typically retains the breathability characteristics of its base material. This makes it an excellent candidate for breathable mechanical stretch fabric for sportswear.

4. What should I look for when sourcing mechanical stretch fabric for a project?

Focus on the key performance specs: stretch percentage, recovery rate, fabric weight, and composition. Clearly define your need for durability, breathability, and hand feel. Partnering with an integrated manufacturer like Suzhou Redcolor, which controls spinning and weaving, ensures consistency and the ability to customize these parameters.

5. Is mechanical stretch fabric more expensive?

The mechanical stretch fabric cost per meter varies widely based on composition, weight, and complexity of construction. While sometimes comparable to mid-range spandex blends, specialized high-performance mechanical stretch fabrics can command a higher price due to their advanced engineering and superior durability in specific applications.

References

[1] Hu, J., & Xin, B. (2018). *Structure and Mechanics of Woven Fabrics*. In *Textile and Fashion Design* (pp. 45-67). Springer, Cham. (This source provides foundational knowledge on how weave structure influences fabric mechanics, relevant to explaining mechanical stretch principles).

[2] Gandhi, K. L. (2019). *Woven Textiles: Principles, Technologies and Applications*. Woodhead Publishing. (A comprehensive text detailing yarn texturing techniques and fabric engineering, supporting the sections on stretch mechanisms and applications).

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English 中文简体

中文简体