The Ultimate Guide to Four-Sided Stretch Fabric: Technology, Applications, and Selection

2026-01-26

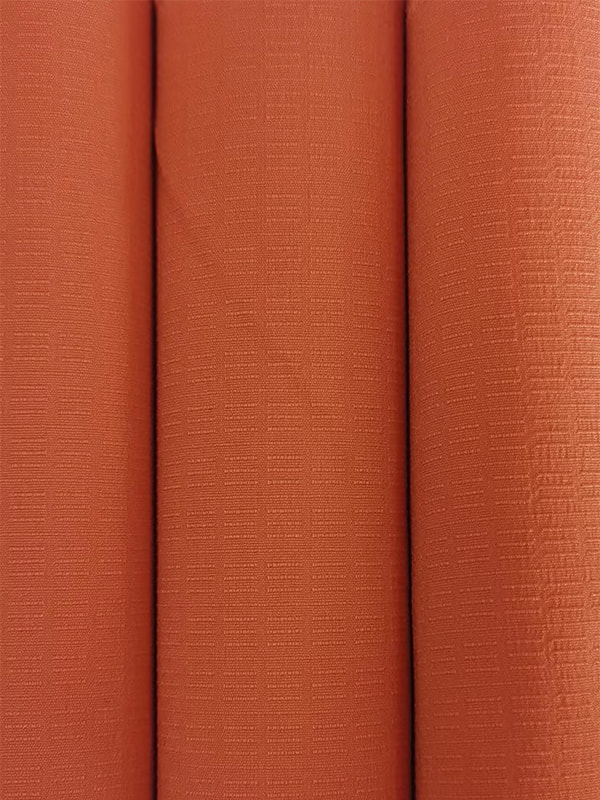

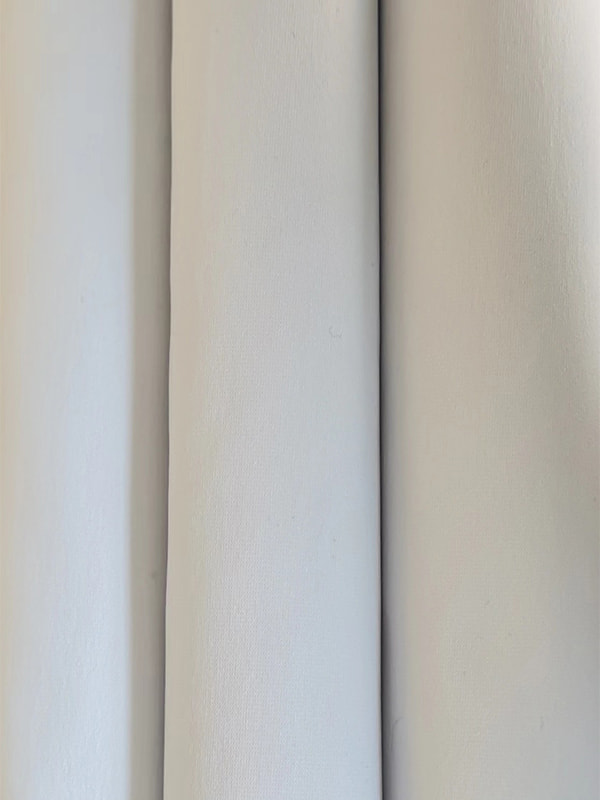

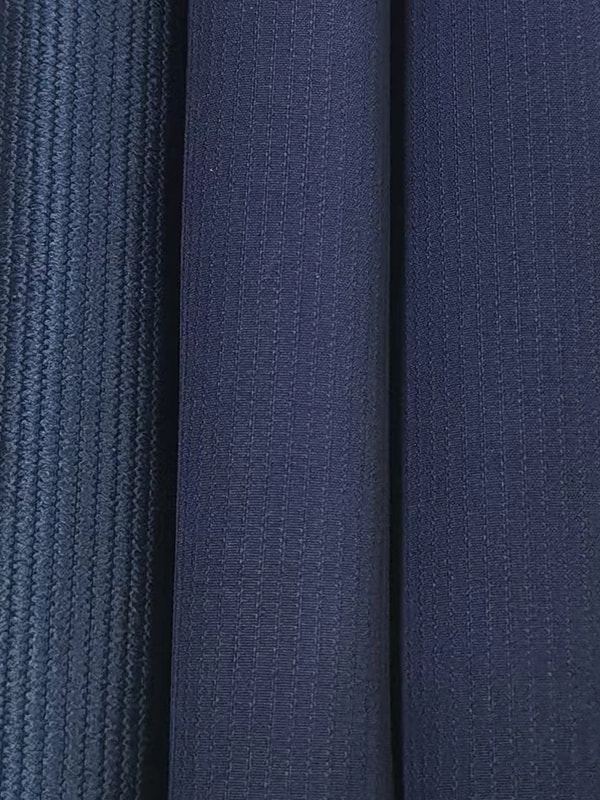

In the dynamic world of technical textiles, innovation is constant. One of the most significant advancements meeting the demand for superior comfort, fit, and performance is Four-Sided Stretch Fabric. Unlike traditional two-way stretch materials, this fabric offers unparalleled freedom of movement and shape retention. For businesses and designers seeking high-quality materials, understanding this technology is key. As a premier textile production enterprise integrating spinning, texturing, weaving, and trade, Suzhou Redcolor International Trading Co., Ltd. leverages its expertise to produce advanced Four-Sided Stretch Fabric for global markets, adhering to a philosophy of high-quality products to serve every customer.

What is Four-Sided Stretch Fabric? The Core Technology Explained

At its core, Four-Sided Stretch Fabric refers to a knitted or woven material engineered to stretch and recover in both the warp (lengthwise) and weft (widthwise) directions. This bi-directional elasticity is achieved through advanced fiber technology and fabric construction, often involving specialized yarns like spandex (elastane) or through unique knitting techniques that create a multi-directional mechanical stretch.

Key Mechanisms Behind the Stretch

Fiber-Based Elastication

- Involves integrating elastic fibers like spandex into the yarn blend.

- The elastic core is wrapped with stable fibers like polyester or nylon.

- Provides consistent, durable, and powerful recovery.

Mechanical or Construction-Based Stretch

- Utilizes specific knit structures, such as double-knit or warp knit patterns.

- Stretch is inherent to the looped construction of the fabric.

- Often offers excellent breathability and a softer hand feel.

Four-Sided Stretch vs. Two-Way Stretch

Understanding the difference between four-sided and two-way stretch is crucial for selecting the right material for an application. The primary distinction lies in the directionality and quality of movement.

While two-way stretch fabric only provides significant give along one axis (typically the width), Four-Sided Stretch Fabric moves comfortably in all directions. This fundamental difference impacts fit, comfort, and durability. For instance, a two-way stretch garment might feel restrictive during complex, multi-planar movements like lunging or twisting, whereas a four-sided stretch garment moves seamlessly with the body. The recovery—the fabric's ability to return to its original shape—is also generally more robust and lasting in high-quality four-sided constructions, reducing bagging or sagging over time [1].

| Feature | Four-Sided Stretch Fabric | Traditional Two-Way Stretch |

|---|---|---|

| Direction of Stretch | Bi-directional (warp and weft) | Uni-directional (usually weft only) |

| Freedom of Movement | Superior, allows for complex, multi-directional motion | Limited, primarily in one plane |

| Shape Retention | Excellent, resists bagging and deformation | Moderate to Poor, may lose shape with wear |

| Common Applications | High-performance sportswear, compression wear, tailored activewear | Basic leggings, simple t-shirts, some casualwear |

Advantages and Diverse Applications of Four-Sided Stretch

The benefits of this fabric extend far beyond simple elasticity, enabling innovation across multiple industries.

Unmatched Benefits for End-Users

- Enhanced Comfort & Fit: Conforms perfectly to body contours without constriction.

- Superior Freedom of Movement: Essential for athletic and occupational activities requiring a full range of motion.

- Improved Durability & Shape Retention: Withstands repeated stress and stretching without becoming misshapen.

- Optimal Performance: Manages moisture, provides support, and allows for aerodynamic or streamlined silhouettes.

Industry Applications

Activewear and Sportswear

This is the primary domain for four-sided stretch fabric for high-intensity workouts. The fabric's ability to move in all planes makes it ideal for yoga, running, cycling, and training apparel where flexibility and muscle support are paramount.

Fashion and Everyday Apparel

The demand for comfort in daily wear has driven the integration of four-sided stretch into jeans, blazers, dresses, and tops. It provides the sleek look of woven fabrics with the comfort of knits.

Medical and Compression Garments

Graduated compression and therapeutic support require precise, consistent pressure, which is achievable with engineered four-sided stretch materials.

Outdoor and Technical Gear

Used in performance outerwear, climbing apparel, and tactical gear where mobility and durability under stress are non-negotiable.

Selecting the Right Four-Sided Stretch Fabric: A Comprehensive Guide

Choosing the appropriate fabric is a technical decision. Here are critical factors to consider, especially for businesses sourcing materials for production.

Critical Performance Parameters

Stretch and Recovery Percentage

- Measured as the fabric's ability to extend and return to its original length.

- High-quality recovery (over 95%) is essential for longevity.

Composition and Fiber Content

- Polyester/Spandex blends: Offer durability, moisture-wicking, and colorfastness.

- Nylon/Spandex blends: Provide a softer feel, excellent abrasion resistance, and a luxurious drape.

- Natural fiber blends (e.g., Cotton/Spandex): Prioritize breathability and comfort for casual wear.

Weight and GSM (Grams per Square Meter)

- Lightweight (150-200 GSM): Ideal for base layers and lightweight activewear.

- Mid-weight (200-300 GSM): Versatile for most sportswear and everyday apparel.

- Heavyweight (300+ GSM): Used for outerwear, winter activewear, and structured compression wear.

Understanding Fabric Construction

The method of construction—whether warp knit, circular knit, or woven with stretch yarns—profoundly affects the fabric's hand feel, opacity, and performance. For example, breathable four-sided stretch fabric for athletic wear is often constructed using advanced circular knitting machines that create tiny pores for ventilation while maintaining structural integrity. In contrast, a woven four-sided stretch might be chosen for trousers requiring a more formal drape.

Overcoming Common Challenges in Production and Care

Working with and maintaining Four-Sided Stretch Fabric requires specific knowledge to preserve its properties.

Manufacturing Considerations

Sewing and cutting stretch fabrics demand specialized techniques to prevent waviness or seam puckering. Using ballpoint needles, polyester-wrapped core threads, and differential feed sewing machines are industry standards. For companies like Suzhou Redcolor International Trading Co., Ltd., with integrated production bases, controlling these parameters from spinning to weaving ensures a consistent, high-quality roll goods that is easier for downstream manufacturers to handle.

Care and Maintenance Best Practices

Proper care extends the life of garments made from these fabrics. Key advice includes:

- Washing in cold water on a gentle cycle.

- Avoiding high heat in dryers and irons, as it can degrade elastic fibers.

- Laying flat to dry when possible to maintain shape.

- Avoiding bleach and fabric softeners, which can coat fibers and reduce elasticity.

Following these steps is particularly important for maintaining the integrity of durable four-sided stretch material for work uniforms that undergo frequent industrial laundering.

The Future of Stretch Fabrics and Sustainable Innovation

The trajectory of Four-Sided Stretch Fabric points towards smarter and more sustainable solutions. The development of eco-friendly four-sided stretch fabric options is a major focus, incorporating recycled polyester (rPET) and bio-derived spandex. Furthermore, innovations are leading to lightweight four-sided stretch fabric for travel clothing that is packable, wrinkle-resistant, and versatile for the modern consumer. The integration of phase-change materials or smart textiles for temperature regulation is also on the horizon, pushing the boundaries of what stretch fabrics can do [2]. As a manufacturer serving global markets, Suzhou Redcolor International Trading Co., Ltd. remains at the forefront of these trends, ensuring its annual output of millions of meters meets evolving demands for performance and responsibility.

Frequently Asked Questions (FAQ)

1. What exactly does "four-sided stretch" mean?

It means the fabric can comfortably stretch in all four directions: up, down, left, and right (technically, along both the lengthwise warp and widthwise weft of the fabric). This provides greater freedom of movement compared to fabrics that only stretch in one direction.

2. Is four-sided stretch fabric durable for everyday use?

Yes, high-quality four-sided stretch fabric is specifically engineered for durability. Its excellent recovery properties mean it resists bagging and sagging, making it highly suitable for everyday apparel, work uniforms, and frequent athletic wear. The durability depends on the fiber composition, construction density, and finishing techniques used.

3. How should I care for garments made from this fabric?

To preserve elasticity and shape, wash in cold water, use a gentle cycle, and avoid chlorine bleach. Tumble dry on low heat or, ideally, air dry flat. High heat is the primary enemy of the elastic components within the fabric.

4. Can four-sided stretch fabric be used for formal or structured clothing?

Absolutely. Advances in weaving and finishing allow for the creation of four-sided stretch fabrics with the drape and appearance of traditional wools, suiting materials, or crisp cottons. This allows for formal blazers, trousers, and dresses that offer hidden comfort and flexibility.

5. Are there sustainable options available in four-sided stretch?

The market is increasingly offering eco-friendly options. These include fabrics made from recycled polyester (often from plastic bottles), sustainably sourced nylon, and newer generations of bio-based or recycled elastane. Look for certifications like GRS (Global Recycled Standard) when sourcing sustainable variants.

References

[1] Hu, J., & Hong, Y. (Eds.). (2018). *Advanced Textile Technology for Sportswear and Performance Apparel*. Springer International Publishing. (Reference for discussion on stretch fabric mechanics and recovery properties).

[2] Muthu, S. S. (Ed.). (2020). *Sustainability in the Textile and Apparel Industries: Production Process Sustainability*. Springer Nature. (Reference for trends in sustainable materials and future innovations in stretch fabrics).

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English 中文简体

中文简体