Double Woven Fabric: The Ultimate Guide to Durability and Versatility

2025-08-04

What is Double Woven Fabric and How It's Made

Double woven fabric represents a significant advancement in textile manufacturing, offering superior strength and durability compared to single-layer fabrics. This specialized textile is created by weaving two distinct layers of fabric simultaneously, which are interconnected at specific intervals to form a unified material. The production process requires precision machinery and skilled craftsmanship to ensure consistent quality throughout the fabric.

The Manufacturing Process

Suzhou Redcolor International Trading Co., Ltd. utilizes state-of-the-art weaving technology to produce high-quality double woven fabrics. The process involves:

- Simultaneous weaving of two separate fabric layers

- Precise interconnection points that bond the layers

- Specialized looms capable of handling dual-layer production

- Quality control measures at every production stage

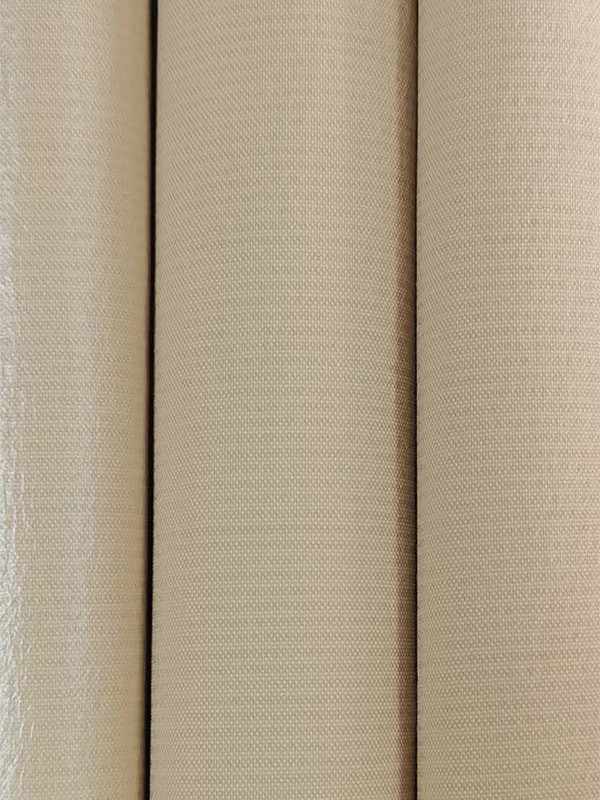

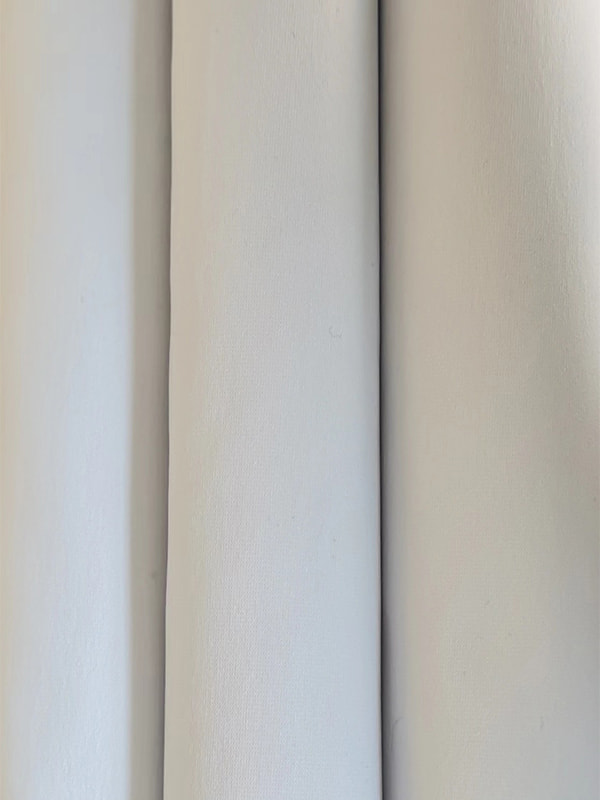

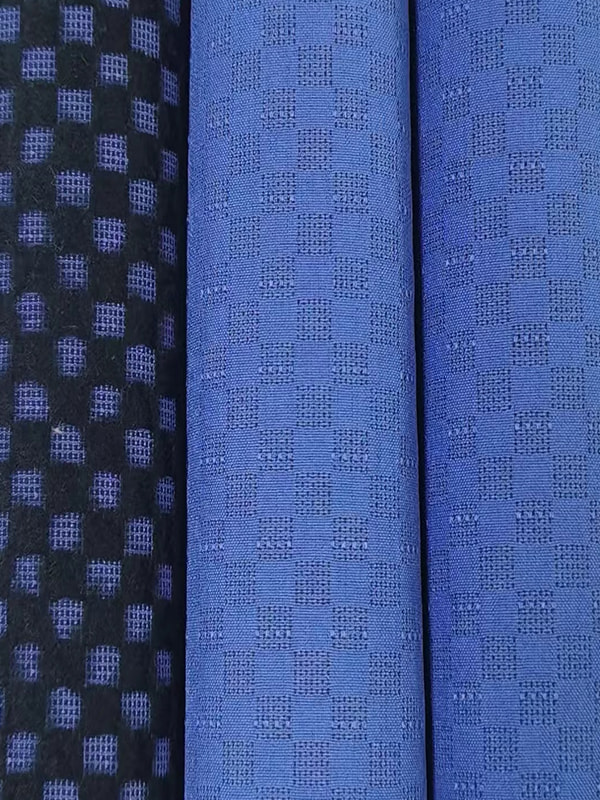

Key Characteristics

Double woven fabrics possess several distinctive features that set them apart from conventional textiles:

- Enhanced durability and tear resistance

- Improved insulation properties

- Greater dimensional stability

- Unique texture and visual appeal

Benefits of Using Double Layer Woven Textiles in Various Applications

The unique structure of double layer woven textiles makes them exceptionally suitable for numerous applications across different industries. Their inherent strength and versatility provide solutions to many common fabric limitations.

Advantages Over Single-Layer Fabrics

When compared to traditional single-layer fabrics, double layer woven textiles offer:

| Feature | Single-Layer Fabric | Double Layer Woven Textile |

|---|---|---|

| Tensile Strength | Moderate | Exceptional |

| Insulation | Basic | Enhanced |

| Durability | Standard | Superior |

Industrial Applications

The robust nature of these textiles makes them ideal for demanding environments:

- Protective workwear and safety equipment

- Heavy-duty transportation and cargo covers

- Architectural and construction applications

- Specialized military and tactical gear

How Durable Double Weave Material Outperforms Conventional Fabrics

Durable double weave material represents a significant leap forward in textile technology, offering performance characteristics that conventional fabrics simply cannot match. The dual-layer construction provides inherent advantages that translate to longer product lifecycles and better performance in challenging conditions.

Performance Comparison

The table below illustrates how durable double weave material compares to standard fabrics in key performance metrics:

| Performance Metric | Conventional Fabric | Durable Double Weave |

|---|---|---|

| Abrasion Resistance | 200-500 cycles | 1,000-2,000 cycles |

| Tear Strength | 10-20 N | 30-50 N |

| Dimensional Stability | 3-5% shrinkage | 1-2% shrinkage |

Long-Term Value Proposition

While the initial cost of durable double weave material may be higher than conventional fabrics, the total cost of ownership is often lower due to:

- Extended product lifespan

- Reduced replacement frequency

- Lower maintenance requirements

- Better performance under stress

The Advantages of Two-Ply Woven Cloth in Specialized Industries

Two-ply woven cloth offers unique benefits that make it particularly valuable in specialized industries where standard fabrics would fail to meet performance requirements. The dual-layer construction provides solutions to challenges faced in extreme environments and demanding applications.

Medical and Healthcare Applications

In healthcare settings, two-ply woven cloth provides:

- Enhanced barrier protection against fluids and contaminants

- Improved durability for reusable medical textiles

- Better patient comfort through optimized breathability

- Superior resistance to repeated sterilization processes

Technical and Performance Apparel

The outdoor and performance apparel industry benefits from:

- Exceptional wind and water resistance

- Improved thermal regulation

- Reduced weight compared to laminated alternatives

- Greater flexibility and comfort in movement

Why Choose Reinforced Dual Layer Fabric for Demanding Environments

Reinforced dual layer fabric represents the pinnacle of durable textile solutions, specifically engineered to withstand the most challenging conditions. This advanced material combines the benefits of double weaving with additional reinforcement techniques for unparalleled performance.

Construction Features

Reinforced dual layer fabric incorporates several key construction elements:

- High-tenacity yarns in both warp and weft directions

- Strategic reinforcement at stress points

- Specialized binding techniques between layers

- Optional coatings or treatments for specific properties

Extreme Environment Performance

These fabrics excel in applications where ordinary materials would fail:

| Environment | Standard Fabric Performance | Reinforced Dual Layer Performance |

|---|---|---|

| High-Temperature | Degrades quickly | Maintains integrity |

| Chemical Exposure | Rapid deterioration | Enhanced resistance |

| Mechanical Stress | Short lifespan | Extended durability |

Innovations in Heavy-Duty Interwoven Textiles Production

The field of heavy-duty interwoven textiles continues to evolve, with manufacturers like Suzhou Redcolor International Trading Co., Ltd. developing new techniques and materials to push the boundaries of what these fabrics can achieve. These innovations are transforming industries that rely on high-performance textiles.

Advanced Manufacturing Techniques

Modern production methods for heavy-duty interwoven textiles include:

- Computer-controlled precision weaving

- Integration of high-performance fibers

- Advanced quality control systems

- Eco-friendly production processes

Future Trends

The next generation of heavy-duty interwoven textiles will likely feature:

- Smart textile integrations

- Enhanced sustainable materials

- Improved comfort without sacrificing durability

- Greater customization options

As a leading manufacturer with extensive production capabilities, Suzhou Redcolor International Trading Co., Ltd. continues to innovate in the field of double woven fabrics, delivering high-quality solutions to markets worldwide. With annual production capacity of around 60 million meters of diverse textiles, the company serves clients across the United States, Europe, and Southeast Asia with reliable, performance-driven textile solutions.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English 中文简体

中文简体