Double Woven Fabric: Definitive Guide to Durability & Applications

2025-08-12

Understanding Double Woven Fabric and Its Unique Structure

Double woven fabric is a type of textile constructed from two distinct layers of woven cloth, which are interconnected during the weaving process. Unlike single-layer fabrics, where only one set of warp and weft threads forms the entire material, double woven fabric features two complete sets of warp and weft. These two layers can be made from the same or different fibers, creating unique properties in terms of strength, insulation, and design flexibility.

Structural Characteristics of Double Woven Fabric

Dual-Layer Construction

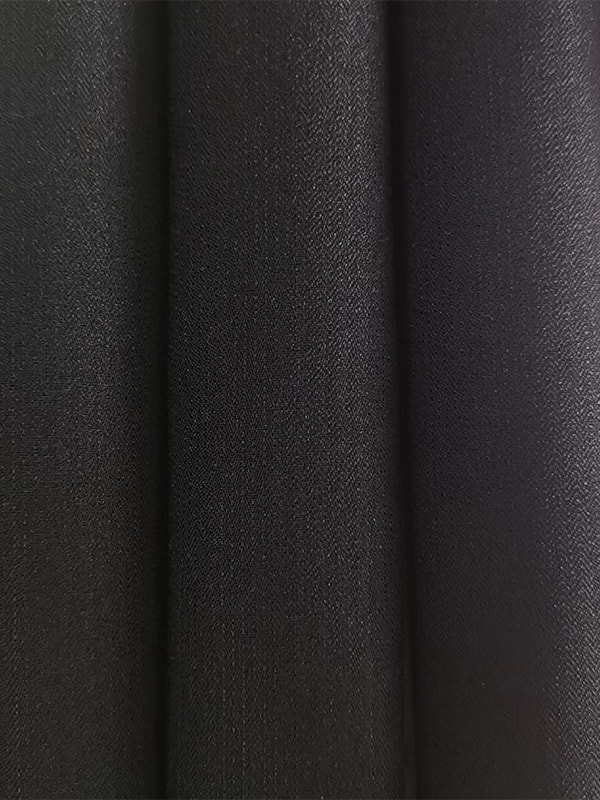

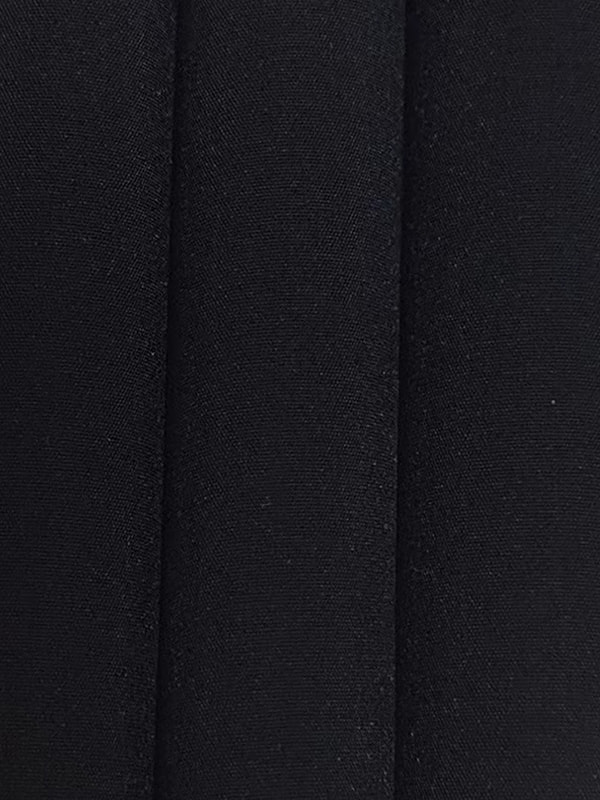

- Layer 1: Serves as the face fabric, often optimized for aesthetics and surface texture.

- Layer 2: Acts as the backing layer, adding structural stability and strength.

- Layers are interlinked at specific intervals to prevent separation and enhance fabric integrity.

Fiber Composition

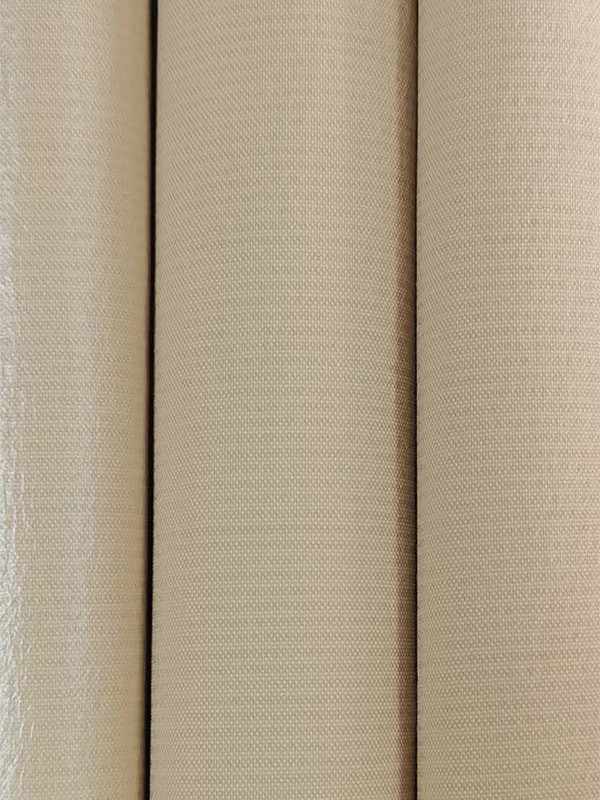

- Can use identical fibers for uniform performance (for example, 100% cotton for breathability).

- Can combine fibers (for example, cotton and polyester) for a balance of comfort and durability.

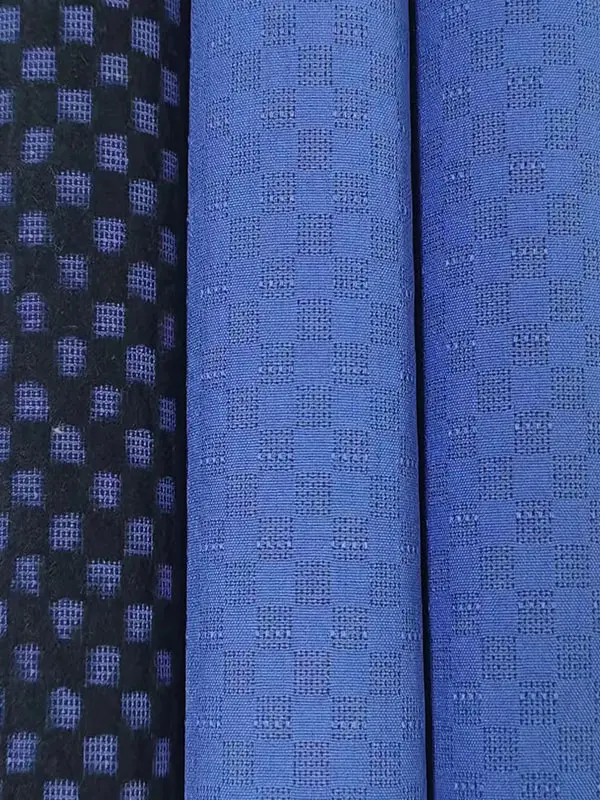

Weave Variations

- Both layers can have the same weave type (plain, twill, satin) or different weaves for functional purposes.

- Patterns and colors can differ between layers, allowing reversible designs.

Parameter Comparison: Double Woven Fabric vs. Single-Layer Fabric

| Property | Double Woven Fabric | Single-Layer Fabric |

| Thickness | 0.8–2.5 mm (depending on fiber & weave density) | 0.3–1.2 mm |

| Weight | 250–500 g/m² | 100–300 g/m² |

| Tensile Strength | 30–50% higher due to dual-layer construction | Standard tensile strength based on weave |

| Thermal Insulation | 1.5–2.0 times higher than single-layer fabric | Lower insulation properties |

| Durability | Extended lifespan in high-friction applications | Shorter lifespan under heavy wear |

| Design Flexibility | High — allows reversible or contrasting patterns | Limited to single surface design |

Unique Advantages of the Structure

- Enhanced Durability – The interconnected layers distribute tension more evenly, reducing localized wear.

- Better Insulation – The air gap between layers improves thermal retention, making it suitable for winter garments and upholstery.

- Design Versatility – Can be made reversible or feature intricate jacquard patterns without sacrificing strength.

- Dimensional Stability – Maintains shape better than lighter fabrics under stress.

Double Woven Fabric: The Ultimate Guide to Durability and Versatility

Double woven fabric is recognized for its exceptional balance between strength and adaptability, making it suitable for a wide range of applications — from heavy-duty upholstery to high-performance outerwear. The unique dual-layer construction directly contributes to its durability, while the flexibility in fiber choice, weave pattern, and finishing methods gives it unparalleled versatility in design and function.

Durability Factors in Double Woven Fabric

Dual-Layer Reinforcement

- Two interconnected layers share and distribute stress, reducing fiber breakage.

- Reinforced interlacing points improve resistance to tearing and abrasion.

Weave Density

- Higher ends-per-inch (EPI) and picks-per-inch (PPI) values result in tighter, stronger fabric.

- Dense weave structures can resist surface pilling and thread distortion under heavy use.

Fiber Strength

- Blending natural and synthetic fibers can enhance tensile strength without sacrificing comfort.

- High-modulus fibers increase fabric stability under load.

Versatility in Applications

- Apparel – Outerwear, jackets, skirts, and trousers that require structure and insulation.

- Home Furnishings – Upholstery, curtains, table runners, and reversible decorative fabrics.

- Technical Uses – Protective covers, industrial filters, and insulated equipment wraps.

- Seasonal Adaptability – Breathable options for summer wear, insulated versions for winter.

Parameter Comparison: Durability and Versatility

| Feature / Metric | Double Woven Fabric | Common Single-Layer Fabric |

| Abrasion Resistance | 40,000–60,000 Martindale cycles before wear | 15,000–30,000 cycles |

| Tensile Strength | 450–700 N (warp) / 350–600 N (weft) | 250–450 N (warp) / 200–400 N (weft) |

| Tear Strength | 25–40 N | 10–20 N |

| Thermal Insulation (R) | 1.0–1.6 m²·K/W | 0.4–0.9 m²·K/W |

| Design Reversibility | High — patterns and colors possible on both sides | Low — one usable side only |

| Application Range | Multi-season, multi-industry | Limited by fabric type and weave |

Why Choose Double Woven Fabric for Both Strength and Flexibility

- Long Service Life – Withstands repeated washing and high-friction use without rapid degradation.

- Customizable Function – Fiber blends and weave designs can be tailored to specific performance needs.

- Enhanced Comfort – Can combine a soft outer layer with a supportive inner layer.

- Eco-Friendly Potential – Designed for long-term use, reducing replacement frequency and waste.

Manufacturing Process of Double Woven Fabric

The production of Double Woven Fabric involves a specialized weaving method that creates two distinct yet interconnected fabric layers. This process requires precision in yarn selection, loom settings, and quality control to ensure the final textile meets desired performance standards for durability, versatility, and design aesthetics.

1. Yarn Selection and Preparation

- Fiber Choice: Natural fibers (cotton, wool, linen) for comfort and breathability; synthetic fibers (polyester, nylon) for strength and resilience.

- Yarn Quality: Uniform thickness, minimal defects, and proper twist levels are critical to avoid weak spots.

- Preparation: Yarns are wound onto warp beams, sized (coated) for added strength, and arranged according to design requirements.

2. Warp and Weft Setup

- Dual Warp Beams: One beam for each fabric layer, allowing independent control of tension and density.

- Weft Insertion: Two or more shuttles carry weft threads for each layer, with interlinking points determined by the weave pattern.

3. Weaving Process

- Layer Formation: Each set of warp and weft forms its own layer within the loom.

- Interlinking Points: Specific picks bind the two layers together, providing stability and preventing separation.

- Pattern Integration: Jacquard or dobby attachments can introduce complex designs on one or both layers.

4. Finishing Processes

- Washing & Relaxation: Removes sizing agents and allows fibers to settle into final dimensions.

- Heat Setting: Stabilizes fabric structure and prevents shrinkage (especially in synthetic blends).

- Surface Finishing: Brushing, calendaring, or coating to achieve desired hand feel, gloss, or functionality.

Parameter Comparison: Double Woven Fabric vs. Single-Layer Fabric in Manufacturing

| Parameter | Double Woven Fabric | Single-Layer Fabric |

| Loom Type | Specialized double-beam loom | Standard single-beam loom |

| Warp Beams Required | 2 or more | 1 |

| Production Speed | 40–70% slower due to complexity | Faster due to simpler construction |

| Weaving Density Range | 40–120 ends/cm (combined layers) | 20–60 ends/cm |

| Fabric Stability | High dimensional stability due to dual structure | Moderate stability |

| Design Capability | Reversible, multi-color, complex patterns | Limited to front-facing designs |

| Material Usage | 1.8–2.2 times more yarn per square meter | Standard yarn usage |

Key Advantages of the Manufacturing Process

- Enhanced Structural Integrity – Interconnected layers ensure the fabric holds its shape under heavy stress.

- Greater Design Freedom – Allows complex reversible patterns without compromising strength.

- Custom Performance Tuning – Fiber blends and weave density can be adjusted for targeted applications such as thermal insulation or abrasion resistance.

How to Select the Best Double Woven Fabric for Your Needs

Choosing the right Double Woven Fabric requires evaluating its structural properties, intended application, and production quality. With its dual-layer construction, this fabric type offers exceptional durability and versatility — but selecting the optimal specification can make the difference between a good fit and the perfect solution.

Suzhou Redcolor International Trading Co., Ltd., headquartered in Suzhou, is an experienced textile manufacturer with integrated spinning, weaving, and trading capabilities. Backed by subsidiaries such as Suzhou LJC Textile Co., Ltd. and Wujiang Jiabaokang Textile Co., Ltd., and supported by production bases in Wujiang, Suzhou, and Siyang, Suqian, the company produces approximately 60 million meters of high-quality fabrics annually. This extensive capacity allows for precise customization of Double Woven Fabric to meet diverse customer requirements in both domestic and international markets, including the United States, Europe, and Southeast Asia.

1. Define the Intended Use

- Apparel: Look for softer fibers and balanced weave density for comfort and drape.

- Upholstery: Opt for higher weave density and abrasion resistance for longevity.

- Technical Applications: Prioritize fiber blends with moisture resistance, insulation, or flame-retardant properties.

2. Evaluate Key Technical Parameters

| Selection Factor | Recommended Range for Double Woven Fabric | Why It Matters |

| Weave Density | 60–100 ends/cm (combined layers) | Higher density improves strength and wear resistance |

| Fabric Weight | 250–500 g/m² | Influences durability, drape, and insulation |

| Tensile Strength | ≥ 450 N (warp) / ≥ 350 N (weft) | Ensures long-lasting structural integrity |

| Abrasion Resistance | ≥ 40,000 Martindale cycles | Critical for upholstery and heavy-use apparel |

| Thermal Insulation (R) | 1.0–1.6 m²·K/W | Important for outerwear and seasonal fabrics |

| Reversibility | Single or double-sided design, as required | Offers design flexibility for multi-use items |

3. Assess Fabric Quality and Consistency

Suzhou Redcolor International Trading Co., Ltd. applies strict quality control in every production stage — from yarn preparation to final finishing — ensuring that Double Woven Fabric maintains consistent thickness, stable dimensions, and defect-free surfaces. Regular testing of tensile strength, shrinkage, and abrasion resistance is performed to meet both domestic and international quality standards.

4. Consider Customization Options

With a versatile production setup and large-scale output, Suzhou Redcolor International Trading Co., Ltd. can tailor:

- Fiber composition (natural, synthetic, or blends)

- Weave patterns (plain, twill, jacquard)

- Surface finishing (brushed, calendared, coated)

- Color and pattern combinations for reversible designs

5. Match the Fabric to Your Market Needs

- High-End Fashion: Lightweight, high-drama reversible designs for unique styling.

- Home Furnishings: Heavyweight, abrasion-resistant textures for extended use.

- Outdoor Gear: Technical fiber blends with weather resistance.

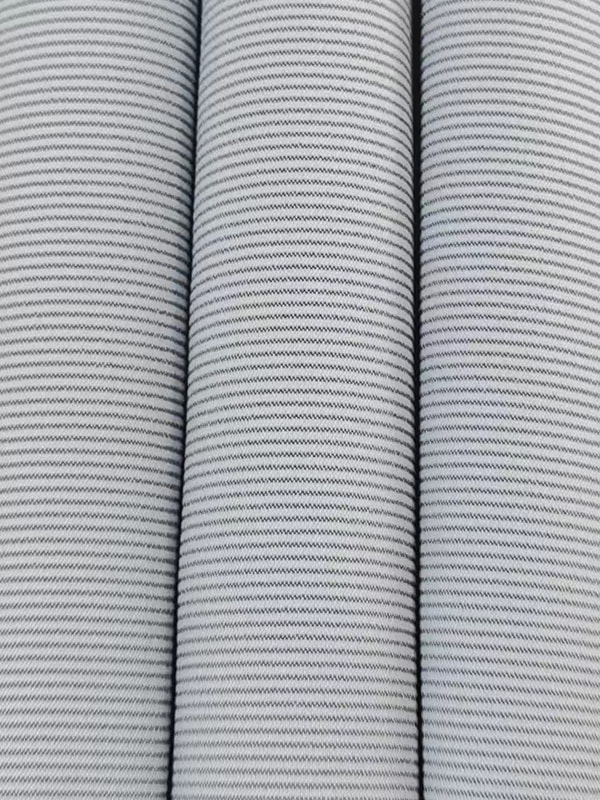

75D/100D 4-Way Stretch Mountaineering Double Weave Fabric - Cationic Brushed Waterproof Fabric

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English 中文简体

中文简体