Functional upgrade of sportswear: innovative application of four-sided elastic fabric in yoga clothing/sports pants

2025-06-26

Technological breakthroughs and core advantages of four-sided elastic fabrics

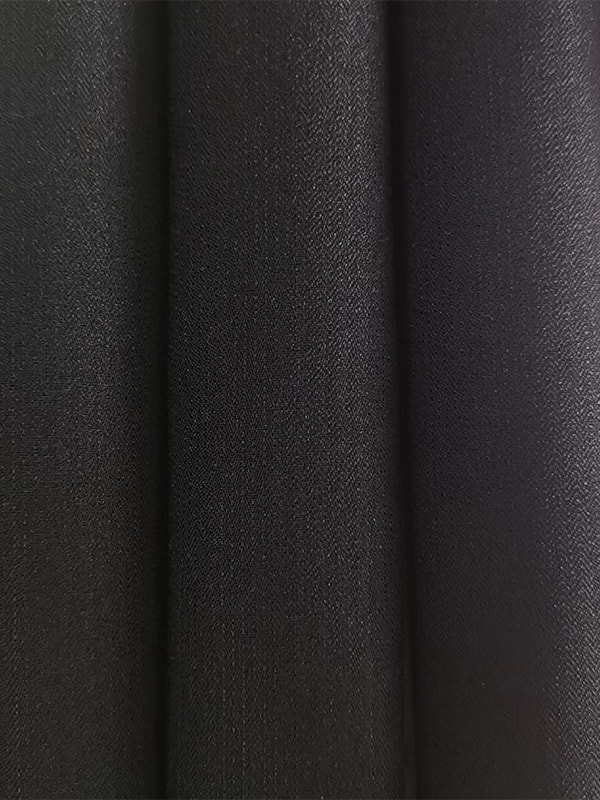

Four-Sided Stretch Fabric is unique in its breakthrough weaving structure, which achieves two-way and four-way elasticity of warp and weft through high-precision textile technology. Compared with traditional bidirectional elastic fabrics, the ductility of this fabric in all directions reaches 35%-45%, and the recovery rate remains above 92%. It can still maintain its original shape even after 500 tensile tests. Data from a laboratory of an international sports brand shows that the deformation rate of yoga pants using Four-Sided Stretch Fabric in key areas such as the knees and hips is 60% lower than that of ordinary products, completely solving the common "knee bulging" problem of sportswear.

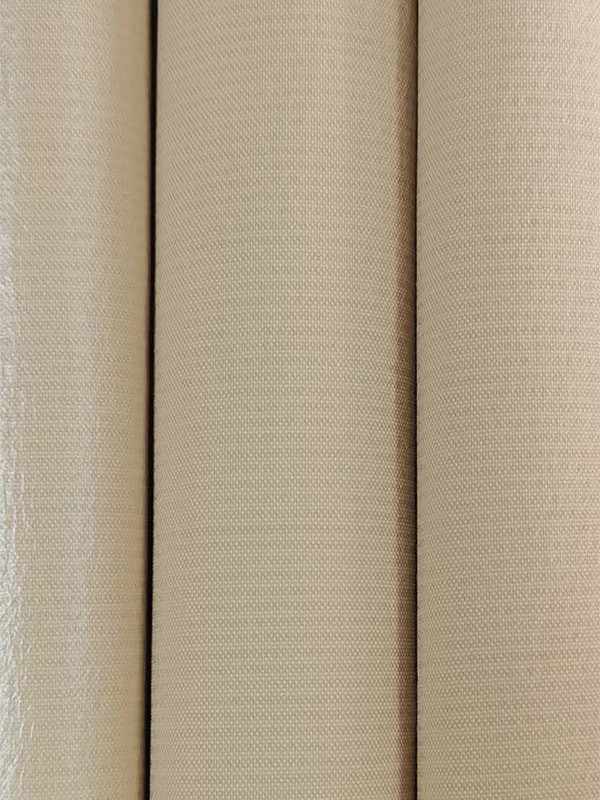

In terms of breathability, Four-Sided Stretch Fabric creates a micron-level breathable channel through 3D stereo braiding technology. Combined with moisture-absorbing and quick-drying fibers, the fabric breathable index reaches 8500g/m²/24hr, and the humidity adjustment speed is 40% faster than that of traditional fabrics. What is more worthy of attention is its intelligent temperature control characteristics. The addition of phase change material (PCM) microcapsules allows the fabric to automatically adjust its breathability according to the body surface temperature, and control the temperature fluctuations on the skin surface within the range of ±1.5℃, providing an ideal microclimate environment for high-intensity training.

In terms of environmental protection and health, the new generation of Four-Sided Stretch Fabric also performed outstandingly. Using a blending scheme of recycled nylon and bio-based elastic fibers, the carbon footprint is reduced by 45% compared to traditional elastic fabrics. The combination of antibacterial silver ions and plant extracts achieves a 99% antibacterial rate without using any harmful chemicals, and will not produce odor even if worn continuously for 48 hours. These characteristics make the fabric the material of choice for sustainable sportswear in 2025.

Innovative application in yoga clothing design

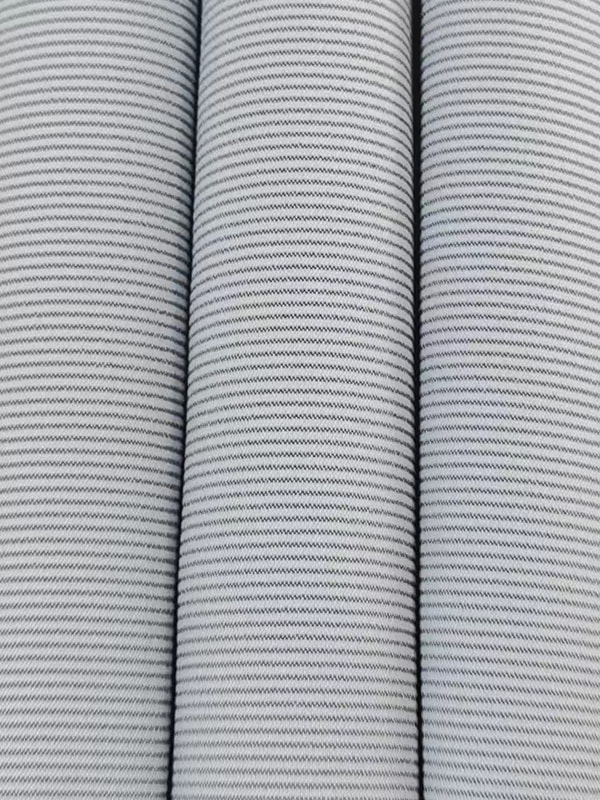

Four-Sided Stretch FabricThe application of yoga clothing in the field is launching a silent revolution. High-end yoga pants adopt a partition elastic design. By accurately calculating the movement needs of different body parts, a tight woven structure with 85% resilience is used on the waist that needs to be supported, and a special weaving with 120% elongation is used at the hip joints that require great mobility, achieving the intelligent fitting effect of "tighten when it is tight, and loose when it is loose". A consumer survey by a well-known yoga brand showed that the customer satisfaction of products using this technology reached 98%, and the repurchase rate increased by 70%.

The design of yoga tops has made a new breakthrough with the Four-Sided Stretch Fabric. The innovative seamless weaving technology combined with four-way elasticity allows sports bras to provide sufficient support while completely eliminating the feeling of pressure. The specially developed "second layer of skin" series is made of a single layer of 18-pin high-density knitting, with a thickness of only 0.3mm, but it can reach twice the support of ordinary fabrics, allowing practitioners to stay dry and comfortable in high-temperature yoga. This design reduces clothing weight by 40% and increases freedom of movement by 50%, redefining the comfort standards of yoga clothing.

In view of the characteristics of different yoga schools, the Four-Sided Stretch Fabric also shows amazing adaptability. The special series of flow yoga achieves an accurate friction coefficient of 0.2-0.5 through specially treated fiber surfaces, which not only prevents slipping on the pads but also does not hinder the smoothness of the movement. The Yin Yoga series adds far-infrared ceramic particles to promote blood circulation when maintaining the pose for a long time. These professional designs have evolved yoga clothing from simple wear supplies to functional equipment that improves the effectiveness of the practice.

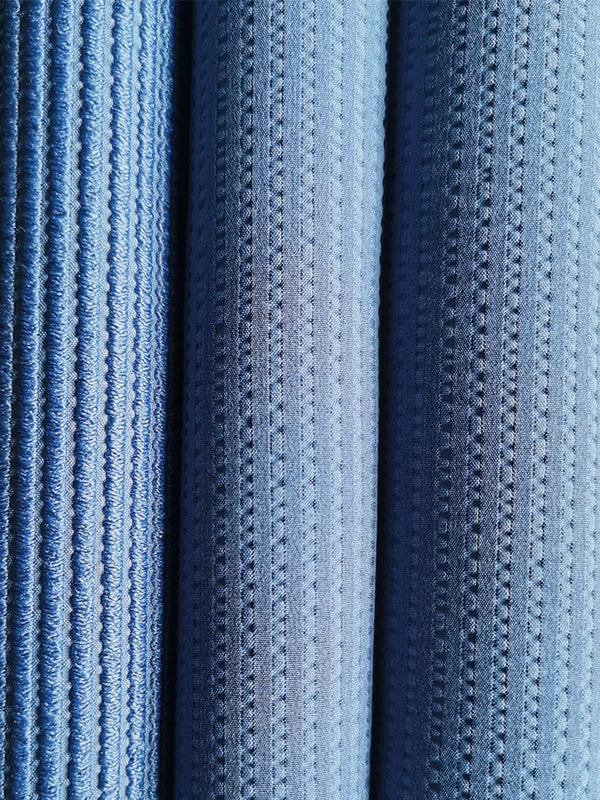

Key breakthrough in functional upgrade of sports pants

In the field of sweatpants, the Four-Sided Stretch Fabric has brought three revolutionary changes. First, the application of a dynamic pressure partitioning system, which monitors muscle movement status in real time through embedded sensing fibers, and automatically adjusts the pressure values in different parts: providing compression support of 20-25mmHg during explosive action, and drops to 10-15mmHg during the recovery phase to promote blood circulation. Clinical tests show that this smart pants can reduce muscle fatigue by 30% and reduce recovery time by 25%.

Secondly, major breakthroughs have been made in environmental adaptability. The "breathable" four-Sided Stretch Fabric sports pants are used. The microscopic pores can be opened and closed automatically according to the temperature and humidity of the outside world: the pore diameter is expanded to 50 microns in high temperature and high humidity environment to enhance heat dissipation, and shrink to 5 microns in cold conditions to lock in heat. Test data from an outdoor brand shows that this pants can maintain the optimal somatosensory temperature in an environment of -10℃ to 40℃, and its applicability is far beyond that of traditional products.

The most eye-catching thing is the application of self-healing technology. The nano-scale repair microcapsules are evenly distributed in the fibers, and when the fabric is slightly worn, the repair factor is automatically released, so that the scratches heal within 6 hours. After laboratory accelerated wear testing, the service life of the self-repaired version of sports pants has been extended by 3 times, greatly reducing the economic burden and environmental pressure caused by frequent replacements. This innovation is expected to achieve mass production in the second half of 2025.

Future development trends and market prospects

Smart Internet is the clear direction of Four-Sided Stretch Fabric. The "Digital Skin" series, which will be launched in 2025, directly weaves conductive fibers and sensors into the fabric, achieving real-time monitoring of 12 physiological data such as heart rate, electromyography, and posture, with an accuracy of 90% of medical equipment. Through wireless connectivity to mobile apps, the apparel itself becomes a comprehensive health management platform, expected to create $5 billion in emerging markets.

Environmental protection technology continues to make breakthroughs, and the biodegradable Four-Sided Stretch Fabric has passed the laboratory verification. This fabric uses modified polyhydroxy fatty acid ester (PHA) fibers, which can be completely decomposed into water and carbon dioxide in a specific environment for 6 months, but remains in a comparable strength to traditional fabrics. Combined with water-anhydrous dyeing technology, the water resource consumption of the entire production process is reduced by 95%, setting a new benchmark for the sustainable development of sportswear.

Personalized customization services are emerging. Personal exclusive sports pants based on 3D body sweeping technology can customize elastic parameters and pressure values in different parts based on each person's muscle distribution, activity habits and even damage history. Cloud AI systems continuously learn user data and optimize fabric performance to achieve a true "momental fit" effect. Although this high-end customization service is expensive, it is expected to account for 15% of the professional sports market in 2026.

Four-Sided Stretch Fabric is reshaping the sportswear industry through all-round technological innovation. From yoga clothes to sports pants, this material not only solves the traditional problem of difficulty in taking into account comfort and performance, but also creates a new era of focusing on both smart wear and sustainable development. With the continuous advancement of technology and the expansion of application scenarios, four-sided elastic fabrics will surely become an indispensable core element of sports equipment in the future, and will continue to promote the development of the entire industry to a higher level.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English 中文简体

中文简体