2025 Fabric Trend Outlook: How T400 Stretch Fabric Leads the Fashion Functional Trend

2025-06-19

Technological Breakthrough and Core Advantages of T400 Stretch Fabric

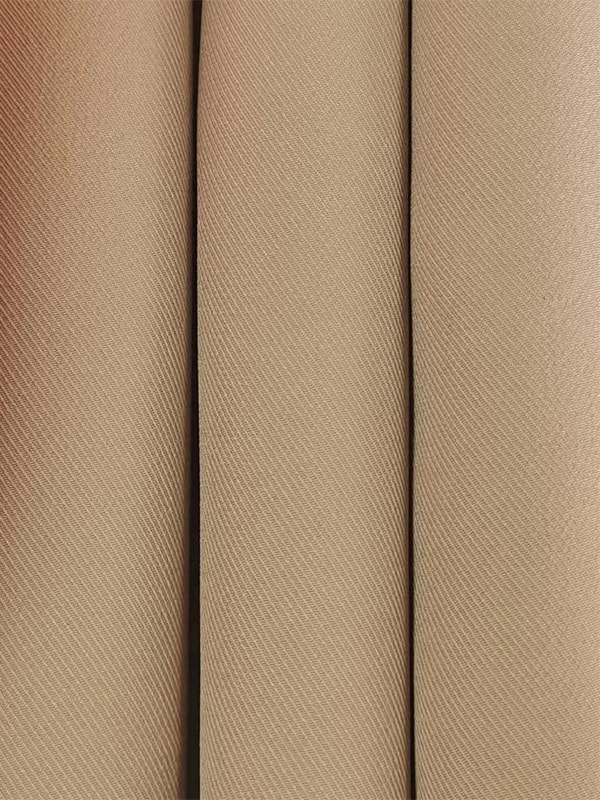

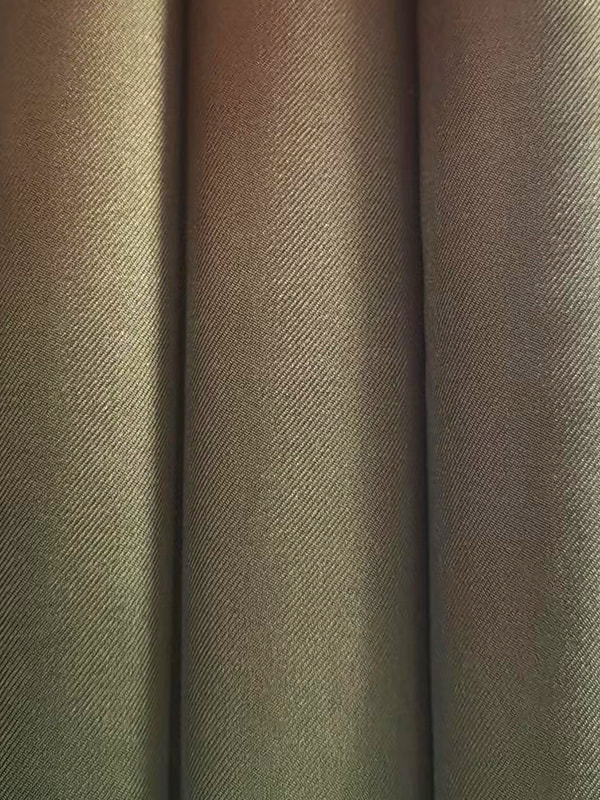

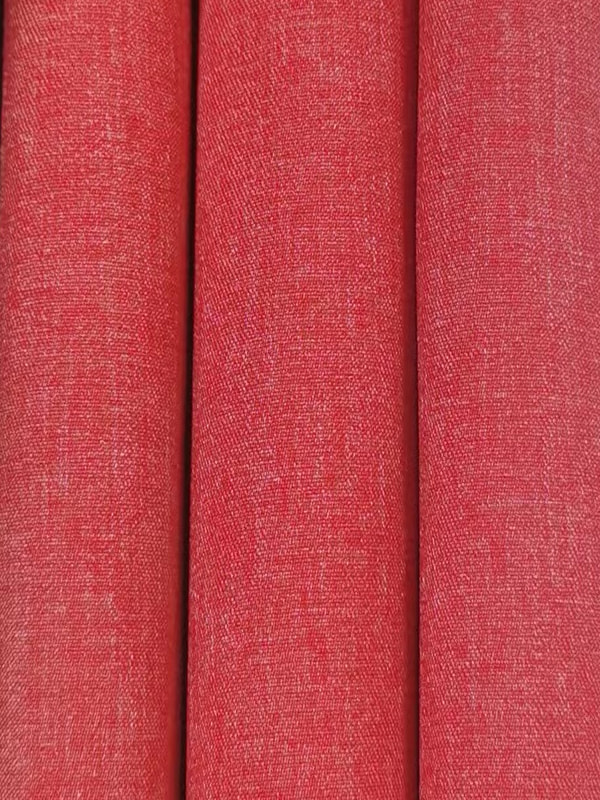

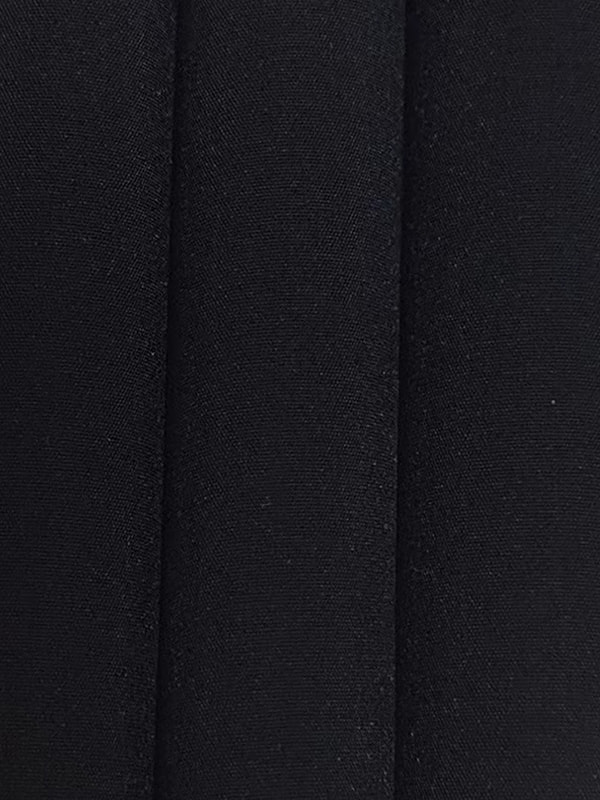

T400 Stretch Fabric's core competitiveness comes from its unique molecular structure design. This fabric uses two-component elastic fiber technology and achieves an elastic recovery rate of 40%-50% through the perfect ratio of polyester and special polyether, which far exceeds the performance of traditional spandex fabrics. Compared with ordinary elastic fabrics, T400 Stretch Fabric has a 300% increase in fatigue resistance, which means that the clothing can still maintain its original shape after long-term wear and repeated stretching, completely solving the problem of traditional elastic fabrics being easy to relax and deform.

In terms of physical properties, T400 Stretch Fabric shows all-round advantages. Its four-way elastic characteristics provide the wearer with all-round freedom of movement, which is particularly suitable for the cross-border needs of sports and daily wear. The fabric density reaches the golden range of 180-220g/m², which not only ensures sufficient stiffness, but also does not add extra weight. Even more amazing is its shape memory function. Even after 500 wash tests, the dimensional stability remains above 97%, which provides designers with unprecedented creative freedom.

Environmental protection is another major technical highlight of T400 Stretch Fabric. The new generation of products uses 30%-50% recycled polyester raw materials, and the carbon footprint is 40% lower than that of traditional elastic fabrics. Some pioneering brands have launched bio-based T400 Stretch Fabric, using plant-derived raw materials instead of petroleum-based materials, making the fabric completely degradable, which perfectly meets the strict requirements of the fashion industry for sustainable development in 2025.

Diversified expansion of fashion application scenarios

T400 Stretch Fabric is creating a silent revolution in the field of high-end fashion. In the 2025 spring and summer series, many luxury brands innovatively used this fabric in the design of suit jackets, breaking the traditional boundaries between formal and casual wear. By precisely controlling the elastic direction of the fabric, designers achieved the contradictory effect of keeping the shoulders straight and the waist naturally slim, creating an "all-weather suit" that is both in line with business etiquette and extremely comfortable. Data from a top Italian brand shows that sales of suits using T400 Stretch Fabric increased by 220% year-on-year, becoming one of the most successful product lines in the brand's history.

Women's clothing design has gained a new expression due to T400 Stretch Fabric. After using this fabric, close-fitting dresses not only show perfect body curves, but also do not produce the "sense of oppression" common in traditional stretch fabrics. The specially designed gradient elastic area provides moderate pressure in areas that need support and maintains a soft touch in areas that need to relax, achieving a "second skin" wearing experience. The 2025 trend report pointed out that the return rate of high-end women's clothing using T400 Stretch Fabric has decreased by 65%, and customer satisfaction has reached a record high.

The sports and leisure field is the first market conquered by T400 Stretch Fabric. The upgraded fabric improves breathability by 50% through the optimized design of moisture absorption and perspiration channels, and with antibacterial silver ion treatment, it perfectly solves the odor problem of sportswear. The intelligent temperature-controlled version of T400 Stretch Fabric can automatically adjust the fiber spacing according to the ambient temperature, and the temperature adaptation range is from -10℃ to 40℃, which truly realizes the wearing concept of "one piece for all seasons".

Cutting-edge breakthroughs in functional innovation

T400 Stretch Fabric's innovation in functionality goes far beyond basic elasticity. The most eye-catching breakthrough in 2025 is the application of "adaptive pressure" technology. By implanting a network of micro-sensors in different areas of the fabric, the clothing can monitor the state of muscle activity in real time and automatically adjust local pressure to provide precise support for muscle groups in motion. Clinical tests have shown that this smart clothing can reduce the rate of sports injuries by 40% and shorten recovery time by 30%.

Self-repair function is another major innovation. Some high-end T400 Stretch Fabric use microcapsule technology to embed special repair factors in the fibers. When the fabric is slightly worn, these factors are automatically released and repair the damage, extending the service life of the clothing by 3 times. Outdoor brand test data shows that after 100 times of intense washing and 200 hours of friction testing, the strength retention rate of the self-repairing version of the fabric is still over 95%.

The integration of health monitoring functions pushes T400 Stretch Fabric to a new level of smart wear. The clever weaving of conductive fibers enables ordinary clothing to have medical-grade functions such as electrocardiogram monitoring and respiratory rate tracking, and the data accuracy reaches 85% of professional equipment. This "invisible technology" design concept makes health monitoring no longer dependent on clumsy external devices, but naturally integrated into daily wear, and is expected to achieve large-scale commercial application in the second half of 2025.

Sustainable development and future trends

T400 Stretch Fabric innovation under the circular economy model is rewriting the rules of the game in the textile industry. Breakthroughs in chemical recycling technology enable elastic fibers in old clothes to be completely decomposed and recycled, and the proportion of recycled materials in new fabrics has increased to 70% without affecting performance. The 100% recycling series launched by a Nordic environmentally friendly brand has achieved closed-loop production from old clothes to new clothes. Each piece of clothing can reduce 3.2kg of carbon dioxide emissions and won the 2025 Global Sustainable Design Award.

Biotechnology has opened up new possibilities for T400 Stretch Fabric. Spider silk protein cultivated in the laboratory is compounded with elastic fibers to create a new material that is 5 times stronger but lighter. The bioelastomer generated by microbial fermentation is not only completely degradable, but also has temperature responsive properties. These innovations have made T400 Stretch Fabric leap forward in both environmental performance and functional performance, and it is expected to enter the mainstream market in 2026.

Digital customization is another important development direction. Personalized T400 Stretch Fabric clothing based on 3D body scanning technology can accurately match each person's body shape and activity habits, achieving the ultimate customization of "one person, one fabric". The cloud-based AI design system can recommend the optimal stretch distribution plan based on the customer's lifestyle, bringing personalized services to an unprecedented level. Industry analysts predict that by 2026, customized T400 Stretch Fabric products will account for 30% of the high-end market.

From technological breakthroughs to fashion revolutions, T400 Stretch Fabric is redefining people's expectations of clothing. It not only solves the long-standing contradiction between fashion and function, but also creates a new model that emphasizes both sustainable development and technological innovation. In 2025, with the emergence of more cross-border applications, this magical fabric will surely have a profound impact on the future development trajectory of the entire textile and apparel industry, bringing consumers an unprecedented wearing experience.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English 中文简体

中文简体