Protection upgrades in extreme environments: How mountaineering fabrics cope with complex climate challenges

2025-06-12

The ultimate test of mountainous environment on mountain fabrics

The challenge faced by Mountaineering Fabric is much more stringent than ordinary outdoor clothing. In death zones above 8,000 meters above sea level, the temperature can drop sharply from 20℃ above zero to minus 40℃ in a short period of time. With polar storms with wind speeds exceeding 100km/h, the wind-cold effect makes the somatosensory temperature lower to minus 60℃. Under these extreme conditions, traditional fabrics often lose sight of the balance between waterproofness, breathability and warmth, resulting in climbers facing the dual risks of losing temperature or overheating.

Ultraviolet radiation increases dramatically with the increase of altitude, and the ultraviolet intensity increases by 10%-12% for every 1,000 meters of increase. In areas above the snow line, the reflection on the snow surface can increase the ultraviolet exposure by 80%. The protection level of ordinary fabric UPF50+ is often short of limiting in this environment. At the same time, the sharp edges and accidental scratches of alpine rocks put forward almost demands on the wear-resistant and tear-resistant properties of Mountaineering Fabric. The superposition of these extreme conditions has driven mountaineering fabric technology to continuously break through the physical limits.

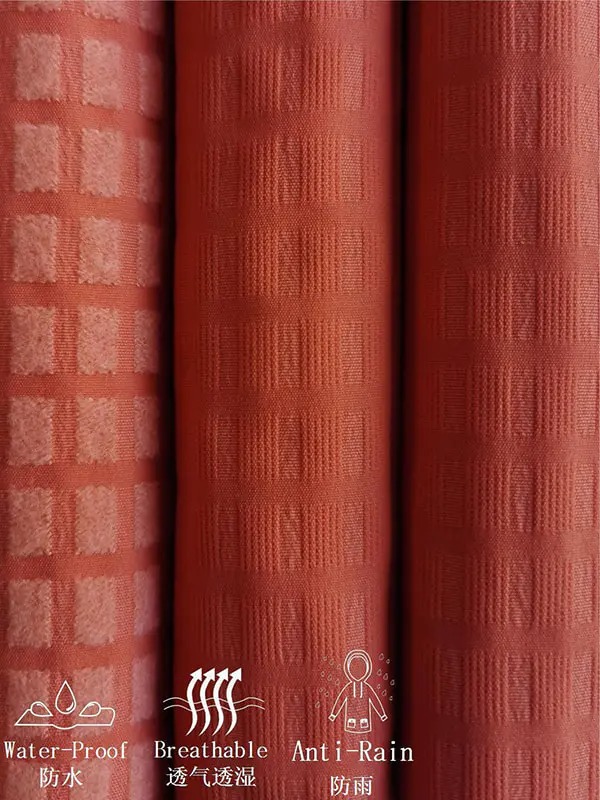

Revolutionary breakthrough in waterproof and breathable technology

The Hyundai Mountaineering Fabric has made a qualitative leap in waterproof and breathable performance. The pore size of the new ePTFE (expanded polytetrafluoroethylene) film is controlled between 0.1-0.5 microns, 700 times smaller than water molecules but 700 times larger than water vapor molecules, achieving true selective penetration. This technology makes the fabric's waterproof index exceed 50,000mm water column pressure, and the breathability reaches 30,000g/m²/24hr, perfectly solving the dilemma of traditional waterproof fabrics "either stuffy or leaking".

Intelligent responsive waterproofing technology is another major breakthrough. Some high-end Mountaineering Fabrics use temperature-sensitive polymers that automatically shrink micropores when the external temperature drops and enhance water resistance, and expand micropores when the temperature rises and improve breathability. The addition of phase change materials (PCM) further optimizes the microclimate regulation, absorbs excess heat during vigorous exercise, releases stored heat when stationary, and controls somatosensory temperature fluctuations within the range of ±2°C.

Seam processing technology has also made great progress. The laser cutting and ultrasonic welding process completely eliminates the hidden danger of water seepage caused by traditional sewing pinholes. Combined with the new hydrophilic tape, the overall waterproof performance of the clothing is improved by 300%. Some top mountaineering suit brands have even achieved "seaterless" design, and have been integrated into 3D weaving technology, fundamentally eliminating the possibility of moisture penetration.

Innovative design of dynamic warming system

Warming technology to deal with extreme low temperatures is the core competitiveness of modern Mountaineering Fabric. The application of aerogel materials has opened a new era of warmth. Aerogel insulation layer with a thickness of only 3mm can provide a warmth effect equivalent to 5cm thick down, and is completely unaffected by the humid environment. This material, once used by NASA in space suits, has now become the standard configuration for high-end mountaineering suits, and can still maintain excellent warmth in -50℃ environment.

Adaptive heating systems represent the latest technology direction. Some intelligent Mountaineering Fabric has built-in micro airflow channel networks that monitor body surface temperature and humidity through biosensors, and automatically adjust the opening and closing degree and airflow direction of the channel. When the body temperature drops, the system will close the air flow channel to form a static air insulation layer; when the body temperature rises, the channel will be opened to enhance convection and heat dissipation, achieving true "breathable" warmth.

Layered warm-keeping technology has also been significantly optimized. The new generation of Mountaineering Fabric adopts a gradient warm design. The inner layer uses moisture-absorbing heating fibers to quickly export sweat and convert heat energy. The middle layer uses a bionic down structure to efficiently lock the temperature, and the outer layer is equipped with a windproof and moisture-permeable membrane to isolate the cold wind. This systematic solution increases overall warming efficiency by 40% and reduces weight by 30%, greatly improving climbers' freedom of movement.

Integrated innovation in all aspects of protection performance

Mountaineering Fabric's protection performance has evolved from a single climate protection to a comprehensive integrated protection system. In terms of ultraviolet protection, specially treated nano zinc oxide fibers can increase the UPF value to 100+, and the protective performance attenuation does not exceed 5% after 50 washes. Some fabrics also have self-healing coatings, and minor scratches can be automatically repaired within 24 hours at room temperature, maintaining a long-lasting protective effect.

Wear resistance and tear resistance have reached a new level. The Mountaineering Fabric blended with ultra-high molecular weight polyethylene (UHMWPE) and aramid has a tear resistance of 8 times that of ordinary nylon fabrics, while reducing weight by 20%. 3D three-dimensional weaving technology enables the fabric to form a reinforced structure in key stress-bearing areas, with a wear resistance index exceeding 50,000 rpm, which is enough to withstand the most harsh alpine environment test.

The safety protection functions are also constantly being improved. Some professional Mountaineering Fabric integrates Recco® reflection system to help search and rescue personnel accurately locate in emergencies such as avalanches. The addition of conductive fibers enables clothing to have basic electromagnetic shielding functions, protecting electronic equipment from interference in extreme weather. These innovations have led modern mountaineering to evolve into a comprehensive safety system by simply protecting equipment.

Future development trends and sustainable directions

With the advancement of materials science, the Mountaineering Fabric is moving towards a smarter and more environmentally friendly direction. Self-energy smart fabrics convert human body movement into electrical energy through friction nanogenerators, supplying power to built-in heating systems or electronic devices. While maintaining ultra-light properties, graphene reinforced fabrics can be adjusted by 5 times, achieving more accurate body temperature management.

Sustainable development has become an industry consensus. Bio-basedMountaineering Fabric uses renewable raw materials such as corn fiber and algae extract, and its carbon footprint is 60% lower than that of traditional petroleum-based fabrics. The closed-loop recycling system allows old mountaineering clothes to be completely decomposed and rebuilt, and some leading brands have achieved mass production of 100% recyclable products. These environmental innovations not only reduce the impact on the alpine ecological environment, but also echo the environmental protection concept of a new generation of climbers.

In the future, with the commercial application of cutting-edge technologies such as quantum dot heating technology and bionic adaptive materials, the performance boundaries of Mountaineering Fabric will continue to expand. But the unchanged core goal is always to provide climbers with the most reliable protection so that mankind can explore the last frontier of the earth more safely. In this eternal dialogue with extreme environments, technological innovation is writing a new chapter.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English 中文简体

中文简体