The Ultimate Guide to Four-Sided Stretch Fabric: Benefits, Uses, and Selection

2025-08-25

What Exactly is Four-Sided Stretch Fabric?

Four-sided stretch fabric represents a significant advancement in textile technology, offering unparalleled flexibility and comfort. Unlike traditional materials that may only stretch in one direction (like along the weft or warp), this innovative fabric is engineered to expand and recover in all four directions: left, right, up, and down. This omnidirectional movement is achieved through the specific knit construction and the integration of elastic fibers like spandex or elastane throughout the entire fabric structure, not just in a single direction. The result is a material that moves seamlessly with the body, providing a freedom that is highly sought after in various applications.

The Core Mechanism Behind the Stretch

The magic of four-way stretch lies in its unique composition and knitting pattern. Typically, these fabrics are knit, which allows for the intricate looping of yarns that can be designed to contract and expand. The most common yarn blend involves a stable base fiber, such as polyester or nylon, combined with a smaller percentage of an elastomeric fiber. This combination ensures that the fabric not only stretches but also has the memory to snap back to its original shape, resisting bagging or permanent deformation over time. The knitting machines are programmed to create a structure where the stitches facilitate movement in every direction, making it distinct from two-way stretch fabrics which are often used in items like leggings that primarily need stretch lengthwise.

Why It's a Game-Changer in Modern Textiles

The introduction and refinement of four-sided stretch material have revolutionized expectations for comfort and performance in apparel and beyond. It caters to the modern demand for clothing that supports an active, dynamic lifestyle without sacrificing style or fit. This fabric allows designers to create garments that are form-fitting yet never restrictive, accommodating a wide range of body types and movements with ease. Its impact is evident across industries, from high-fashion runways to professional athletic wear, making it a cornerstone of contemporary textile innovation.

Key Advantages of Utilizing 4-Way Stretch Materials

Choosing a fabric with four-sided stretch offers a multitude of benefits that extend far beyond simple comfort. These advantages make it a superior choice for a wide array of products, enhancing both functionality and user experience.

Unmatched Freedom of Movement

The most prominent benefit is the complete freedom of movement it provides. Whether for athletic pursuits, dance, or everyday activities, the fabric moves in perfect synchrony with the body. This eliminates the feeling of being constrained by one's clothing, allowing for a full range of motion without any pulling, tugging, or resistance. For athletes, this means clothing that supports performance rather than hindering it, enabling deeper stretches, more powerful movements, and greater agility.

Superior Comfort and Fit

Four-way stretch fabrics conform to the body's contours, creating a customized, second-skin fit that is both flattering and incredibly comfortable. This adaptive quality ensures that the garment fits well on various body shapes and sizes, reducing the need for extensive sizing options. The fabric gently hugs the body without compressing too tightly, providing support where needed while maintaining overall comfort throughout the day. This makes it ideal for both form-fitting activewear and everyday garments where ease of wear is paramount.

Enhanced Durability and Shape Retention

High-quality four-sided stretch fabric is renowned for its durability and ability to maintain its shape wash after wash. The synthetic fibers commonly used, such as nylon and polyester, are inherently strong and resistant to abrasion, pilling, and general wear and tear. The elastic components are integrated in a way that allows them to recover fully after stretching, preventing the fabric from becoming loose or saggy over time. This resilience translates to a longer lifespan for products made from this material, offering better value and reducing waste.

Diverse Applications: Where Four-Sided Stretch Fabric Excels

The unique properties of this fabric make it exceptionally versatile, finding its way into numerous domains. Its application is limited only by the imagination of designers and engineers.

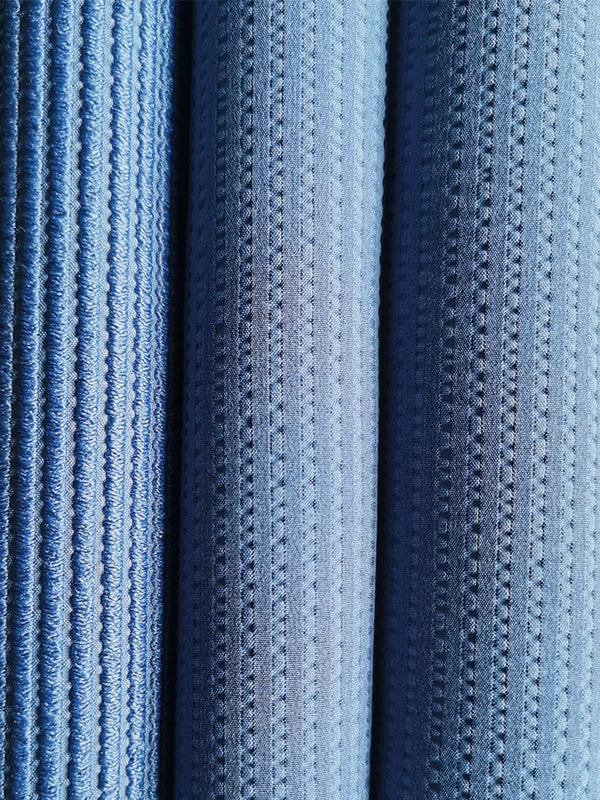

Revolutionizing Active and Athletic Apparel

In the world of sportswear, four-way stretch fabric for athletic wear is the undisputed champion. It is the go-to material for virtually every type of athletic garment because it meets the rigorous demands of physical activity.

- Yoga and Pilates Attire: Allows for deep stretching and complex poses without any restriction.

- Running and Cycling Gear: Provides muscle support, reduces chafing, and offers aerodynamic benefits.

- High-Intensity Training Apparel: Withstands explosive movements and repetitive stretching while maintaining its form.

- Swimwear: Offers excellent fit and comfort, both in and out of the water, and dries quickly.

The fabric's moisture-wicking capabilities, often combined with its stretch, make it a complete performance package for athletes.

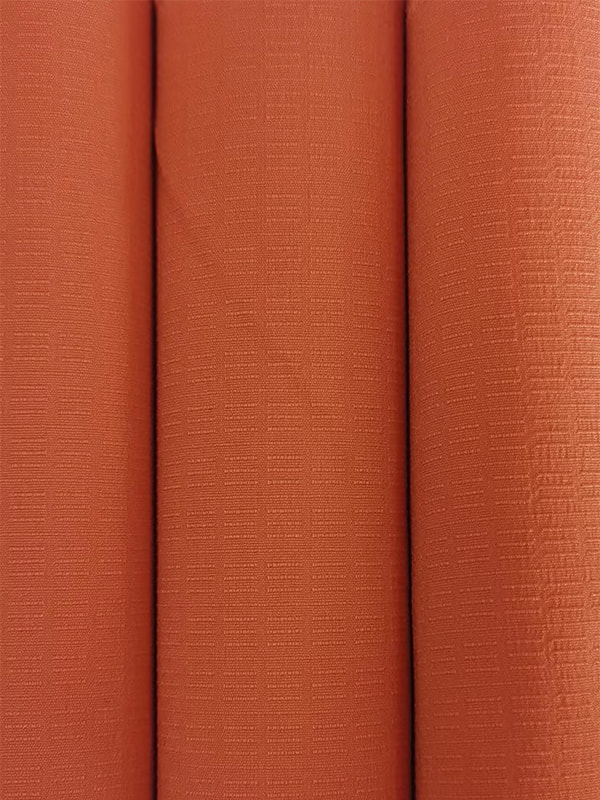

Elevating Everyday Fashion and Outerwear

Beyond the gym, this fabric has dramatically influenced mainstream fashion. Designers are increasingly using comfortable four-way stretch clothing for everyday items to add a new dimension of comfort to style.

- Denim and Pants: Stretch denim and trousers offer a sleek silhouette without the stiffness of traditional fabrics.

- Dresses and Skirts: Create flowing, body-conscious designs that are easy to wear all day.

- Blazers and Structured Jackets: Incorporate hidden stretch panels for ease of movement while maintaining a sharp, tailored look.

- Comfort-Focused Casual Wear: Used in loungewear, t-shirts, and leggings for ultimate daily comfort.

This integration of performance features into daily fashion underscores a growing consumer desire for versatile, comfortable, and practical clothing.

Specialized Uses in Medical and Support Garments

The adaptive and supportive nature of the fabric makes it invaluable in the medical field. It is a critical component in compression garments with four-way stretch, which are designed for therapeutic purposes.

- Post-Surgical Garments: Provide consistent, even pressure to reduce swelling and support healing tissues.

- Athletic Recovery Wear: Aids in muscle stabilization and improves blood circulation after intense exercise.

- Medical Support Stockings: Help manage conditions like lymphedema and deep vein thrombosis (DVT).

The four-way stretch ensures the compression is applied uniformly, regardless of the body's position or movement, enhancing the garment's effectiveness and comfort.

Choosing the Right Fabric: A Buyer's Considerations

Selecting the appropriate four-sided stretch fabric requires careful consideration of several factors to ensure it meets the specific needs of the end product.

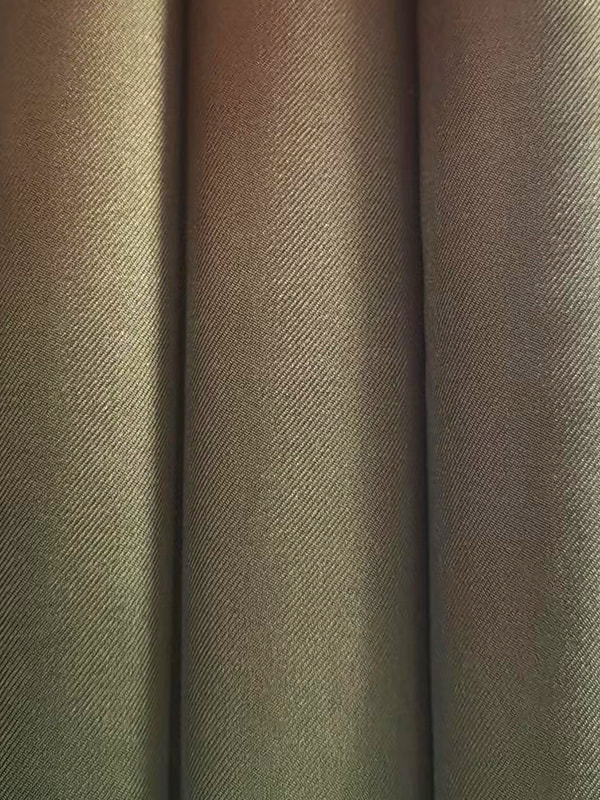

Understanding Composition and Quality

Not all stretch fabrics are created equal. The blend of fibers determines the hand feel, performance, and durability. A common high-performance blend is 90% Polyester / 10% Spandex, which offers excellent moisture-wicking, durability, and recovery. Nylon-Spandex blends are known for their softness and brilliant color retention. The weight of the fabric, measured in GSM (grams per square meter), is also crucial; lighter weights (e.g., 180 GSM) are great for lightweight activewear, while heavier weights (e.g., 300 GSM) provide more compression and are suitable for outerwear or support garments.

Stretch and Recovery Percentage

This is a critical technical specification. Stretch percentage measures how far the fabric can stretch beyond its original length (e.g., 50% stretch). Recovery percentage measures how completely it returns to its original size. Excellent recovery is above 95%, meaning the fabric will not become baggy. For activities requiring significant movement, like gymnastics, a higher stretch percentage is vital. For structured apparel that only requires ease of movement, a lower stretch percentage may be sufficient.

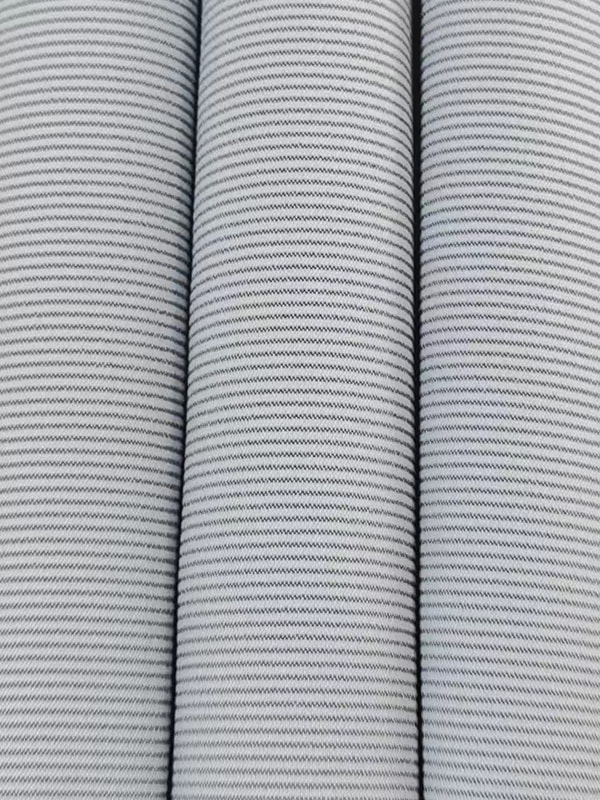

Four-Sided Stretch vs. Two-Sided Stretch: A Detailed Comparison

While both types of stretch fabrics offer flexibility, they serve different purposes and have distinct characteristics. Understanding the difference is key to making an informed choice. Two-way stretch fabric stretches in only one direction, typically along the horizontal weft threads. In contrast, four-way stretch fabric stretches and recovers in both the horizontal (weft) and vertical (warp) directions, offering multidimensional movement.

The following table outlines the key distinctions between these two types of stretch fabrics:

| Feature | Two-Way Stretch Fabric | Four-Way Stretch Fabric |

|---|---|---|

| Direction of Stretch | Stretches in one direction only (usually horizontally). | Stretches in all four directions (left, right, up, down). |

| Freedom of Movement | Good for basic movement in one plane. | Excellent for complex, multi-directional movement. |

| Common Applications | Leggings, swimwear (older styles), simple activewear. | High-performance athletic wear, compression garments, modern fashion. |

| Fit and Conformity | Provides a snug fit but can feel restrictive in other directions. | Offers a superior, second-skin fit that conforms to all body contours. |

| Technical Complexity | Simpler construction and generally lower cost. | More complex knit construction, often commanding a higher price. |

As the table demonstrates, differences between two-way and four-way stretch are significant. Four-way stretch is the technologically advanced option, chosen for applications where unrestricted movement and perfect conformity are non-negotiable.

Caring for Your Four-Sided Stretch Garments

Proper maintenance is essential to preserve the integrity, appearance, and elasticity of these specialized fabrics over time. Incorrect care can damage the elastic fibers and ruin the garment's fit.

Washing and Drying Best Practices

To ensure the longevity of your durable four-way stretch material, follow these care instructions meticulously:

- Washing: Always turn garments inside out before washing. Use cold water on a gentle cycle. Hot water can break down the elastic fibers (spandex/elastane) and cause them to lose their ability to snap back.

- Detergent: Use a mild detergent. Avoid using bleach or fabric softeners, as these chemicals can coat the fibers and degrade the elastane, reducing stretch and promoting odor retention.

- Drying: The best method is to air-dry flat away from direct sunlight. If you must use a dryer, choose the lowest heat setting or a tumble-dry without heat. High heat is the primary enemy of stretch fabrics.

- Ironing: It is generally not recommended. If necessary, use a very cool iron and place a cloth between the iron and the garment.

Adhering to these guidelines will protect your investment and keep your garments performing and looking their best for years to come.

Addressing Common Wear and Tear

Even with excellent care, stretch garments can eventually show signs of use. Pilling can occur, especially in areas of friction. Use a fabric shaver or pill remover to gently restore the surface. If the garment loses some of its elasticity, it is often a sign that the elastic fibers have been damaged by heat or chemicals, and this damage is usually irreversible. Preventing damage through proper care is always more effective than trying to repair it.

The Future of Stretch Fabrics

The evolution of four-sided stretch fabric is far from over. Innovation continues to drive the category forward, with a strong focus on sustainability and enhanced performance. The development of eco-friendly four-way stretch options is a major trend. This includes using recycled polyester and nylon from post-consumer plastic bottles and fishing nets, as well as exploring bio-based elastane alternatives. Furthermore, smart textiles are being integrated with stretch fabrics, embedding sensors to monitor biometrics like heart rate and muscle activity directly into the garment. As technology advances, we can expect four-sided stretch fabric to become even more intelligent, sustainable, and integral to our daily lives.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English 中文简体

中文简体