T800 Stretch Fabric: A Deep-Dive Guide to Performance, Breathability, Four-Way Stretch, and Compression Applications

2025-08-18

Understanding t800 stretch fabric for activewear

What makes T800 compelling for performance apparel

When designers and sourcing teams evaluate t800 stretch fabric for activewear, they look for a balanced portfolio of traits that hold up from the cutting table to the athlete’s daily grind. In practical terms, that means consistent elasticity, dependable recovery after repeated deformation, abrasion resistance in high-friction zones, and a hand feel that stays comfortable against skin during sweat events and long wear times. The “T800” label typically refers to a high-tenacity synthetic base paired with elastane, engineered for an agile modulus curve: soft initial stretch for ease of motion, followed by controlled resistance that stabilizes the garment without feeling restrictive. This balance allows training tops, base layers, and tights to move freely while maintaining shape and support. Equally important is dye affinity and color fastness; garments should retain vibrancy after detergent cycles, UV exposure, and perspiration salts. Because activewear is frequently laundered, dimensional stability under heat and mechanical agitation is critical; high-quality T800 constructions use compact knits and calibrated elastane content to minimize torque, curling, and seam distortion. Designers also appreciate cutting efficiency: stable selvedges and low rolling edges reduce waste and speed up production. Finally, modern consumers expect sustainability signals, so mills increasingly match T800 performance with recycled inputs and reduced-impact dye routes without sacrificing the crisp recovery that athletes love.

Key performance indicators to monitor

- Stretch & recovery profile across weft and warp, verified after multiple load cycles.

- Abrasion resistance in seat, inner-thigh, and underarm panels to mitigate pilling.

- Moisture management (wicking rate, drying time) for thermal comfort during intervals.

- Opacity under strain for bottoms and midlayers, especially in deep squats or lunges.

- Color fastness to washing, perspiration, and light to retain a premium appearance.

How T800 compares in day-to-day training wear

In practice, T800 behaves like a modern, dialed-in performance knit. Versus generic polyester knits with minimal elastane, it feels livelier at the same body temperature and resists bagging at elbows and knees after long sessions. Compared with cotton-spandex jerseys, T800 dries notably faster and resists shape distortion, which matters when garments are washed repeatedly. Against nylon-spandex blends, T800 can offer better color retention and a slightly drier hand, favoring hot studio classes or outdoor heat. These differences are subtle in the showroom but very real during repeated training cycles.

| Property | T800 Stretch Knit | Generic Poly/Low Elastane | Nylon/Spandex Blend | Cotton/Spandex Jersey |

|---|---|---|---|---|

| Recovery after 50 cycles | High; shape retention remains stable | Moderate; gradual bagging | High; may soften over time | Moderate; more deformation after wash |

| Drying time | Fast | Moderate | Fast to moderate | Slow |

| Color fastness | Strong wash/light performance | Acceptable; fades sooner | Good; sensitive to some finishes | Moderate; prone to dulling |

| Hand feel under heat | Dry-touch, supportive | Drier but less elastic | Slick-cool, slightly denser | Softer but clingy when wet |

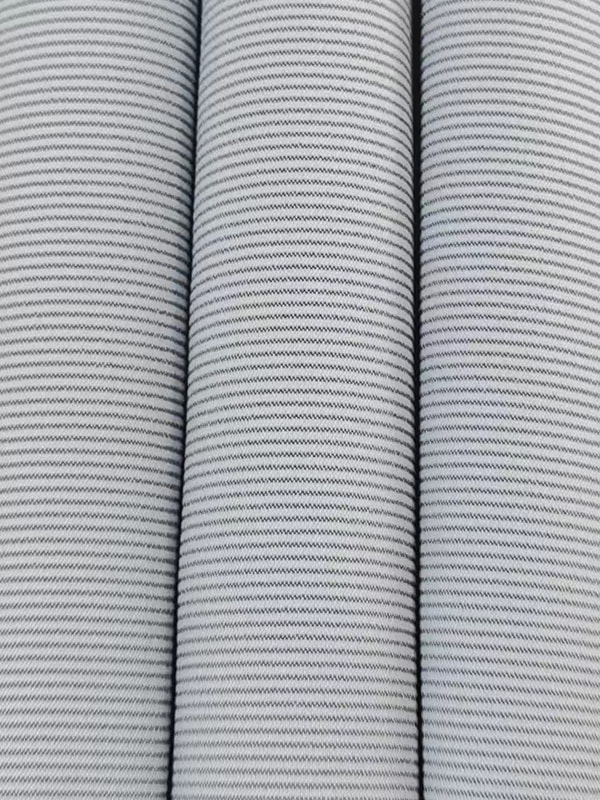

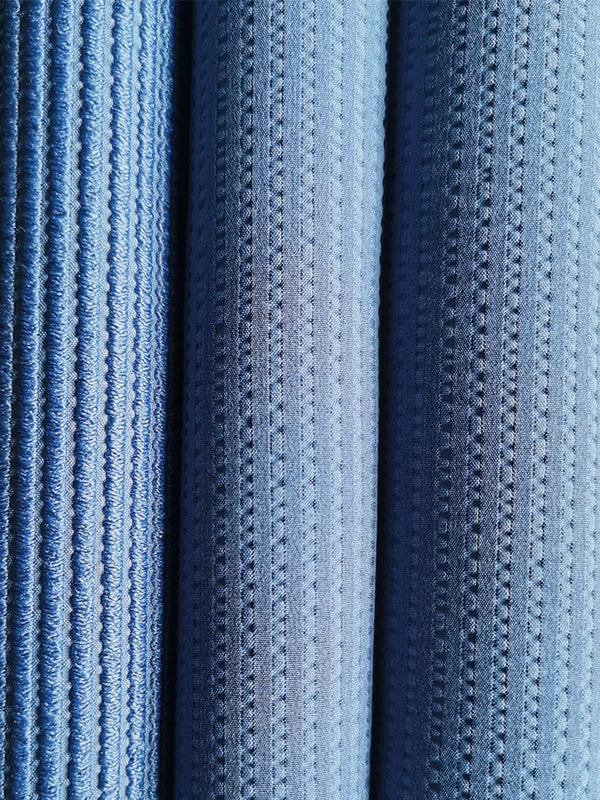

Composition and Performance of the t800 polyester spandex blend

Fiber architecture and why it matters

The backbone of the t800 polyester spandex blend is a high-tenacity polyester filament engineered for durability, dimensional stability, and dye performance, combined with a calibrated elastane proportion that defines the garment’s movement and recovery. The polyester contributes resilience, wrinkle resistance, and color clarity, while elastane introduces elastic energy and fit stability. Mills can tune the denier and filament cross-sections to achieve a matte or micro-sheen aesthetic, as well as to influence capillary pathways that support wicking. Knit structure—double-knit interlock, warp knit tricot, or circular jersey—further modulates compression, drape, and airflow. Interlocks produce smoother faces and stable edges for leggings and fitted tops; jerseys drape more freely and breathe more openly; warp knits offer directional stability suited for contour panels. Additive finishes may enhance moisture transport or reduce cling, yet the most durable performance comes from engineering those traits into the yarns and construction rather than relying solely on surface chemistry. For quality assurance, teams scrutinize weight (GSM), thickness, gauge, and elastane content to avoid see-through, rolling, or premature pilling in high-stress regions.

Design levers the blend gives you

- Adjustable compression via elastane percentage and loop density without sacrificing comfort.

- Control over sheen and hand through filament shape and knit type for brand-right aesthetics.

- Thermal tuning by varying GSM and porosity for cold gyms or hot, humid trails.

- Printing and colorwork that stays crisp due to polyester’s dye affinity and dimensional stability.

Comparing typical constructions used in blends

While the t800 polyester spandex blend targets performance balance, construction choices shape the outcome. Interlock T800 feels dense and supportive, great for squat-proof bottoms. Jersey T800 breathes and drapes more, ideal for tees and base layers. Warp knit T800 locks in fit with minimal curl, favored for precision panels. The table shows how these constructions diverge in compression, airflow, and opacity:

| Construction | Compression Feel | Airflow/Breathability | Opacity at Stretch | Edge Stability |

|---|---|---|---|---|

| Interlock T800 | High, uniform | Moderate | Excellent, squat-ready | High |

| Jersey T800 | Moderate, flexible | High | Good; depends on GSM | Moderate; may curl |

| Warp Knit T800 | Targeted, directional | Moderate | Very good | Very high |

Mobility and Recovery in t800 four-way stretch material

Why true four-way matters for athletes and daily movers

The phrase t800 four-way stretch material signals bidirectional elasticity across both course and wale, which translates to freedom of movement during compound patterns—think deep squats, lateral shuffles, yoga binds, or trail scrambles where you load fabric at multiple angles. True four-way stretch distributes strain more evenly, lowering stress at seams, waistbands, and knee darts. The result is reduced seam pop, fewer blowouts, and a stable silhouette that feels custom-fitted as you move. Recovery is the twin pillar; without elastic recoil, even generous stretch yields bagging and shade lines at knees or elbows. T800’s engineered recovery curve restores panel geometry after repeated elongation, keeping garments crisp through a session and back to form in the locker room. This is particularly helpful for coaches and commuters who rotate outfits multiple times a week and expect a consistent look wash after wash.

Fit engineering with pattern and panel choices

- Use graded negative ease strategically in zones with higher elastane yield to achieve support without discomfort.

- Incorporate gussets and articulation at hips and knees to share strain and preserve recovery over time.

- Balance curved seams with stable grain alignment so stretch potential remains uniform under load.

- Test waistband structures with power-mesh liners to keep vertical creep at bay during jumps or sprints.

Comparative mobility snapshot

Compared with single-direction stretch knits, t800 four-way stretch material spreads elongation more evenly, trimming peak stress by a noticeable margin. Versus purely mechanical-stretch polyester, T800 offers superior recoil and lower post-workout bagging. When set against high-elastane nylon blends, T800 often feels drier and less clingy at elevated heart rates. The table summarizes common mobility observations:

| Fabric Type | Directional Stretch | Recovery After Load | Seam Stress in Deep Flex | Perceived Cling in Heat |

|---|---|---|---|---|

| T800 Four-Way | Four-way | High | Low to moderate | Low |

| Single-Way Stretch Knit | One primary axis | Moderate | Higher at cross-grain | Moderate |

| Mechanical-Stretch Poly | Limited bidirectional | Moderate | Moderate | Low to moderate |

| High-Elastane Nylon | Four-way | Very high | Low | Moderate to high |

Moisture and Thermoregulation with breathable t800 athletic fabric

The science of staying cool and dry

Comfort during training is governed by a delicate loop: sweat generation, wicking to the fabric surface, airflow that promotes evaporation, and heat transfer away from the skin. A well-engineered breathable t800 athletic fabric supports this loop by offering capillarity that pulls moisture off the skin, a surface that spreads droplets for quicker evaporation, and a knit architecture that lets air cycle through without collapsing during movement. Polyester filaments in T800 are sculpted to promote directional wicking channels, while the knit’s micro-porosity dictates how easily humid air escapes. Designers can further tune the sensation with brushed interiors for warmth in cool gyms, or slicker faces for rapid slide under outer layers. Importantly, breathability should be balanced with coverage: the goal is to maintain opacity at stretch so athletes can focus on form, not transparency. By choosing the right GSM and loop density, mills can deliver fabrics that breathe under effort yet remain squat-ready for high-intensity sessions.

Practical ways to enhance cooling in finished garments

- Place mesh or pique zones at heat maps (upper back, underarm, behind knee) to accelerate airflow without compromising structure.

- Leverage body-mapping with thinner gauges near core vents and denser knits at high-friction zones.

- Use seam placements that encourage convective flow rather than block it with bulky joinery.

- Choose matte finishes that resist sweat shine, improving perceived dryness and visual confidence.

Breathability comparisons across common options

In side-by-side wear tests, a breathable t800 athletic fabric tends to dry faster than cotton-dominant knits and holds shape better than lightweight jerseys that go clingy when wet. Against dense interlock nylons, it often feels airier at similar GSM. The table below distills typical thermoregulation differences noted by product teams:

| Material | Wicking Speed | Dry-Time After Intervals | Air Permeability (Relative) | Opacity When Wet |

|---|---|---|---|---|

| Breathable T800 | Fast | Short | High | High; remains confident |

| Cotton-Rich Knit | Moderate | Long | Moderate | Moderate; can shadow |

| Dense Nylon Interlock | Fast | Moderate | Lower | Very high |

| Lightweight Poly Jersey | Fast | Short | Very high | Variable; may show at stretch |

Pattern Making and Use Cases for t800 compression leggings fabric

Dialing in support, opacity, and comfort

The best t800 compression leggings fabric delivers a firm hug without cutting off mobility or comfort. Achieving this balance starts with accurate negative ease across sizes, carefully graded to maintain comparable pressure regardless of body type. Designers map compression by panel—denser interlock or higher elastane content at quads and hamstrings for muscle containment, slightly more forgiving zones behind the knee for fold comfort, and stabilized waistbands to prevent creep during plyometrics. Opacity is non-negotiable: adjust GSM and loop density so fabric remains confidently squat-proof in bright rooms and under camera flash. Seams should be placed to minimize friction paths; flatlock or clean, low-bulk joins reduce chafe risk and eliminate hotspots in long sessions. Because leggings see high abrasion at the seat and inner thigh, prioritizing pilling resistance and robust color fastness keeps the product looking premium through dozens of wash cycles. Finally, consider the tactile narrative—matte to reduce glare, or a subtle micro-sheen to telegraph technical performance—while ensuring the interior feel stays soft against the skin.

Sizing strategies and construction tips

- Use multi-panel waistbands with hidden stabilization to prevent rolling without over-tightening.

- Reinforce crotch and inner-thigh seams; insert gussets to distribute stress and preserve recovery.

- Test opacity on the largest size at full flex; set GSM accordingly rather than scaling linearly.

- Specify abrasion and pilling thresholds appropriate for cycling, rowing, or floor-based training.

Compression-focused comparison for bottoms

T800 leggings typically provide a supportive, dry-touch feel compared with slicker nylon blends, and they resist post-session bagging better than lightweight jerseys. Versus cotton-spandex options, T800 dries faster and holds shape under repeated squats, lunges, and sprints. The following table consolidates common findings from fit labs and wear tests:

| Criterion | T800 Compression Leggings | Nylon/Spandex Leggings | Cotton/Spandex Leggings | Light Poly Jersey Bottoms |

|---|---|---|---|---|

| Compression Consistency | High; even across sizes | High; slightly slick feel | Moderate; loosens over time | Low; not intended for compression |

| Opacity in Deep Squat | Excellent at proper GSM | Very good | Variable; may shadow | Variable; may show |

| Dry-Touch Comfort | Dry, supportive | Cool, slightly slick | Soft but clingy when wet | Light but less supportive |

| Shape Retention Post-Workout | Strong recovery | Strong; may soften with age | Moderate | Low |

Care and lifecycle notes

- Wash cold, gentle cycle; avoid high heat to preserve elastane integrity and color brightness.

- Line dry or low tumble; excess heat accelerates spandex fatigue and dimensional change.

- Turn garments inside-out to reduce surface abrasion and pilling during laundering.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English 中文简体

中文简体