The Ultimate Guide to Twill Stretch Woven Fabric: Uses, Properties, and Care

2025-12-05

Welcome to the definitive resource on Twill Stretch Woven Fabric, a highly versatile and increasingly popular textile in the modern apparel and technical fabric industry. This fabric brilliantly combines the visual appeal and durability of a traditional twill weave with the superior comfort and movement provided by integrated stretch fibers. Our goal is to provide a comprehensive, expert-level understanding of this material, from its technical composition to practical tips on its care and utilization. Whether you are a designer, a textile student, or a home sewer, gaining a deep appreciation for its unique structure and performance characteristics will elevate your work and purchasing decisions. We will explore everything from its inherent properties, compare its durability against alternatives, and offer essential guidance on sewing and garment maintenance to ensure your projects and products excel.

Understanding the Unique Structure and Composition

What Makes Twill Stretch Woven Fabric Distinct?

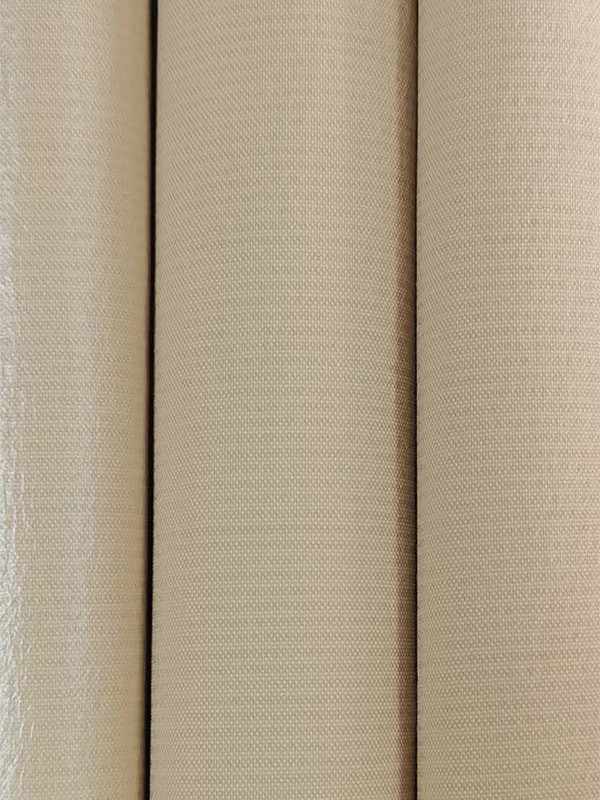

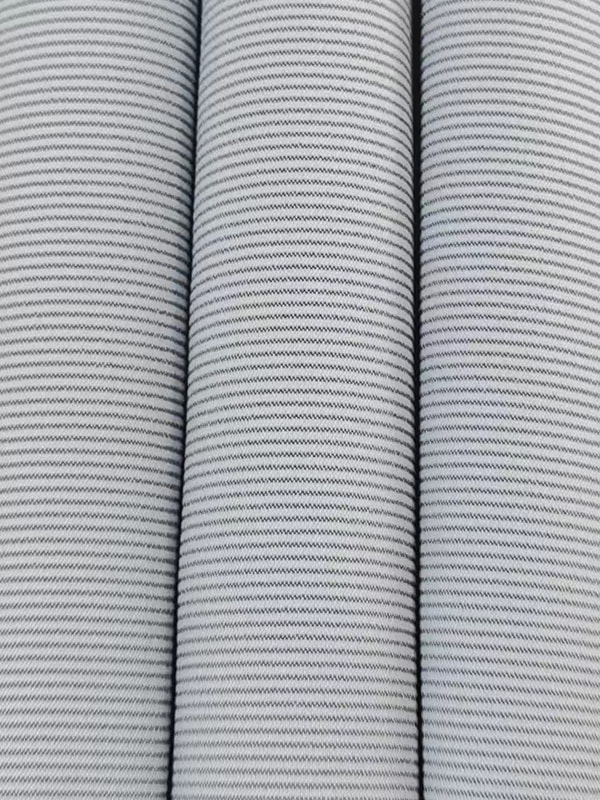

The defining characteristic of twill stretch woven fabric lies in its construction. Unlike plain weaves, the twill weave creates a diagonal pattern or rib, giving the fabric excellent drape, superior durability, and a signature visual texture. The "stretch" component is typically achieved by incorporating elastane (Spandex/Lycra) fibers into the yarn blend, which are then woven into the structure, usually in the weft (horizontal) direction. This integration provides mechanical give without compromising the stability of the woven structure, ensuring garments maintain their shape even after repeated use. This balance of aesthetic texture, robust construction, and dynamic comfort is what sets it apart in the textile landscape, making it suitable for high-wear areas and form-fitting designs. The fiber content can vary widely, from cotton blends for casual wear to specialized synthetic blends for technical performance apparel, all while maintaining that essential diagonal rib and flexibility.

- Weave Pattern: The classic diagonal rib of the twill weave offers natural wrinkle resistance and high thread count per square inch, contributing to its density and lifespan.

- Stretch Mechanism: The incorporation of elastic fibers, typically $2\%$ to $8\%$ of the total blend, is key to achieving two-way or four-way stretch capability.

- Hand and Drape: It generally possesses a moderate weight and excellent recovery, meaning it springs back to its original shape after being stretched, a critical feature for tailored clothing.

- Primary Fibers: Common blends include cotton, rayon, nylon, and especially polyester, each influencing the final aesthetic, breathability, and cost of the material.

Unlocking Applications: Best Uses for Twill Stretch Woven Fabric

Apparel Versatility: From Formal Wear to Activewear

The versatility inherent in this material answers the question of the best uses for twill stretch woven fabric across numerous sectors. Its combination of a polished look and functional stretch makes it ideal for modern, movement-friendly clothing that doesn't sacrifice professionalism or style. In the realm of formal and business wear, it has revolutionized suit separates and structured trousers, allowing for comfortable all-day wear without the restrictive feeling of traditional woven wools. For casual and contemporary fashion, it is the bedrock for comfortable, yet stylish, chinos, skirts, and blazers. Moreover, its moisture-wicking properties and robust structure have made it a favorite in the activewear market, perfect for hiking trousers, golf apparel, and durable yoga pants that require both flexibility and abrasion resistance. This broad range of application is a testament to its exceptional engineering.

- Business Attire: Perfect for professional trousers, skirts, and light blazers that require comfortable movement and wrinkle resistance.

- Casual Wear: Used extensively for tailored shorts, jeans-style pants, and everyday jackets due to its superior shape retention.

- Performance/Activewear: Excellent for outdoor and technical clothing where mobility, durability, and a structured fit are essential.

Practical Applications Beyond Clothing

While apparel is its primary domain, the structural integrity and aesthetic appeal of twill stretch woven fabric lend themselves to several non-clothing uses. Its durability and clean finish make it a viable option for specialized home textiles, particularly items that require some give or need to maintain a taut shape over time. This includes high-end slipcovers for furniture that require a snug, custom fit, and decorative pillow covers that benefit from the diagonal texture. Furthermore, in the accessories market, the fabric is used for durable, structured tote bags, backpacks, and various types of cases that need to resist wear and tear while retaining a premium look. The ability to manage both form and function outside of traditional garments solidifies its status as a highly engineered and flexible material.

| Application Sector | Key Benefit of Stretch Twill | Examples |

| Home Furnishings | Snug fit and abrasion resistance for long-term use. | Tailored sofa slipcovers, dining chair cushions. |

| Bags & Accessories | Structure retention and durable finish. | Structured tote bags, laptop sleeves, gear cases. |

Performance Deep Dive: Polyester Twill Stretch Woven Fabric Properties

In-Depth Look at Key Performance Metrics

When discussing polyester twill stretch woven fabric properties, we are generally focusing on a blend that maximizes synthetic advantages: low cost, high durability, and superior moisture management. Polyester inherently provides excellent resistance to stretching, shrinking, and many chemicals, which, when combined with the twill weave, results in a fabric that holds its press and shape exceptionally well. The inclusion of a stretch component further enhances its functionality, mitigating the rigid feel that $100\%$ woven polyester can sometimes exhibit. This blend is particularly valued in high-activity or professional settings because it dries quickly, resists wrinkles effectively, and can often be engineered for superior colorfastness, making it a low-maintenance, high-performance option favored for uniforms and travel wear. Understanding these inherent qualities is crucial for selecting the right material for demanding applications.

- Wrinkle Resistance: High polyester content coupled with the twill weave dramatically reduces the need for ironing.

- Moisture Management: Polyester fibers are naturally hydrophobic, leading to quick-drying properties, which is excellent for active or humid environments.

- Abrasion Resistance: The tight, durable twill weave, especially with synthetic fibers like polyester or nylon, makes the fabric highly resistant to pilling and scuffs.

- Color Retention: Polyester accepts dye very well, leading to vibrant colors that resist fading even after extensive washing and sun exposure.

Material Showdown: Twill Stretch Woven vs Knit Fabric Durability

Comparing Weave Structure and Resilience

A key comparison for designers is the difference between woven and knit construction, especially when considering the twill stretch woven vs knit fabric durability. Woven fabrics, by definition, consist of two sets of yarns (warp and weft) interlaced at right angles, creating a stable, structurally rigid, and less permeable material. In contrast, knit fabrics are formed from a single yarn looped together, which naturally offers more inherent stretch but can be more susceptible to snags, runs, and permanent deformation (bagging out). The twill weave, in particular, has a denser structure than a standard plain weave, lending it superior tear strength and higher resistance to abrasion. While a high-quality interlock knit may offer more stretch, the woven structure of stretch twill provides greater shape retention, crisper drape, and significantly higher resistance to tearing and pilling over the garment's lifespan, making it the more durable choice for structured or hard-wearing applications.

- Woven Structure: Interlacing provides superior dimensional stability and a firmer hand, minimizing sagging.

- Knit Structure: Looping provides maximum stretch and comfort but can be prone to running and stretching out of shape permanently.

| Feature | Twill Stretch Woven Fabric | Knit Fabric (e.g., Jersey) |

| Durability/Tear Strength | High (Strong structural integrity) | Moderate (Can be prone to runs/snags) |

| Shape Retention (Recovery) | Excellent (Snaps back well) | Good to Moderate (Can bag out over time) |

| Stretch Mechanism | Engineered (via elastic fibers) | Inherent (via looping) |

| Wrinkle Tendency | Low to Moderate | Moderate to High |

Expert Advice: Sewing with Twill Stretch Woven Fabric Tips

Preparation and Cutting Techniques

Successfully creating garments from this material requires specific attention to the "stretch" element; hence, understanding sewing with twill stretch woven fabric tips is essential. Proper preparation begins with pre-washing and drying the fabric as you intend to treat the final garment. This crucial step pre-shrinks the material and helps stabilize the elastic fibers before cutting. When laying out the pattern pieces, pay careful attention to the grainline, ensuring the direction of maximum stretch is aligned appropriately with the area of the body that requires the most movement, typically horizontally (around the body). Use sharp tools, such as rotary cutters or sharp dressmaker shears, to achieve clean, crisp edges. This is particularly important with twills, which can sometimes fray easily if the cut is dull. Avoid clipping the edges excessively, as the woven nature means once a thread is cut, it can pull and fray further into the seam allowance. Always use appropriate weights and minimal pinning to prevent distortion during the cutting process.

- Pre-Shrinking: Always wash and dry the fabric before cutting to prevent final garment shrinkage or distortion.

- Pattern Layout: Ensure the direction of the greatest stretch (often the weft/cross-grain) aligns with the horizontal movement of the body.

- Cutting Tools: Use very sharp shears or a rotary cutter to ensure clean, precise cuts and minimize fraying.

Stitching and Finishing Strategies

When stitching twill stretch woven fabric, the primary concern is ensuring the seams can stretch along with the fabric without popping. The most fundamental tip is to use a specific type of needle—a universal or stretch needle, size 70/10 to 80/12, is typically recommended—to prevent skipped stitches and damage to the elastic fibers. Thread tension should be slightly looser than usual to accommodate the give of the fabric. Crucially, a stretch stitch or a narrow zigzag stitch (e.g., $0.5$mm wide, $2.5$mm long) must be employed for all structural seams that are intended to stretch, such as waistlines, side seams of fitted pants, and sleeve insertions. For areas that do not require stretch (like facings or hems), a straight stitch can be used, but it should still be pressed carefully to maintain the twill's drape. Finishing raw edges is also important; while a serger is ideal, a zigzag or faux overlock stitch is necessary to prevent the edges from unraveling, which is a common issue with woven twills.

| Action | Recommended Tool/Setting | Reason |

| Needle Selection | Universal or Stretch Needle (70/10 or 80/12) | Prevents damage to elastic fibers and reduces skipped stitches. |

| Seam Stitch | Narrow Zigzag or specific Stretch Stitch | Allows the seam to stretch without breaking when the wearer moves. |

| Pressing | Low-to-Medium Heat (with press cloth) | Prevents melting or scorching of synthetic fibers, preserves stretch integrity. |

Longevity Guaranteed: How to Care for Twill Stretch Woven Garments

Washing, Drying, and Ironing Best Practices

Ensuring the longevity of your garments requires knowing **how to care for twill stretch woven garments**, specifically focusing on protecting the integral elastic fibers from heat degradation. The general rule is to be gentle. Machine wash on a cool or warm cycle with a mild detergent—hot water can damage the stretch component and cause the fabric to set into wrinkles. Avoid harsh bleaches. When drying, the best practice is air-drying or hang-drying whenever possible, as machine dryers expose the elastic fibers to excessive heat, which degrades their elasticity over time, leading to "bagging" or loss of recovery. If you must use a machine, use the lowest heat setting and remove the garment while it is still slightly damp. Ironing, if necessary, should be done with a low-to-medium setting, ideally using a press cloth to protect synthetic blends from direct heat contact. Following these mild maintenance steps will ensure the fabric maintains its characteristic shape, stretch, and resilience for years.

- Washing: Use cold or warm water and a delicate or permanent press cycle; avoid harsh chemicals and fabric softeners which can coat and stiffen the elastic fibers.

- Drying: Air-dry flat or hang dry; if machine drying, use the lowest heat setting or tumble dry with no heat.

- Ironing: Use a low-to-medium heat setting (synthetic setting) and always iron on the reverse side or use a pressing cloth.

Conclusion: The Future of Dynamic Textiles

Twill Stretch Woven Fabric represents a perfect synthesis of aesthetic tradition and modern performance technology. Its durability, signature drape, and comfortable give have solidified its position as a go-to material for high-quality, long-lasting apparel that meets the demands of an active lifestyle. By adhering to the specialized sewing and care tips outlined above, you can maximize the lifespan and potential of this exceptional textile.

FAQ

What are the main drawbacks of using Twill Stretch Woven Fabric?

While Twill Stretch Woven Fabric offers numerous benefits, its primary drawbacks relate to its care and potential fiber content. Many high-performance versions contain synthetic fibers (like polyester or nylon) and elastane, making them susceptible to damage from high heat—hot washing or drying can permanently degrade the stretch component (elasticity) and shorten the garment's life. Furthermore, some denser twill weaves may not be as breathable as lightweight cottons or linens, which is an important consideration for hot-weather wear. Due to the tight weave, it can also be prone to fraying at raw edges, necessitating diligent seam finishing, as highlighted in the **sewing with twill stretch woven fabric tips** section.

Is Twill Stretch Woven Fabric suitable for upholstery projects?

Yes, but with caveats. The material's woven structure and inherent durability, as discussed when comparing **twill stretch woven vs knit fabric durability**, make it a strong candidate for light-duty upholstery, such as decorative cushions or specialized slipcovers requiring a tailored fit. However, for heavy-duty, commercial-grade, or high-traffic furniture, a purpose-made upholstery fabric is generally recommended. If using a standard apparel-grade stretch twill, ensure it is a heavier weight, contains a durable synthetic blend (like **polyester twill stretch woven fabric properties** often feature), and is backed or lined to enhance its tear resistance and stability over a large surface area.

How does the type of stretch (2-way vs 4-way) affect the best uses for the fabric?

The type of stretch significantly dictates the **best uses for twill stretch woven fabric**. 2-Way stretch, where the fabric stretches only in one direction (usually the weft/cross-grain), is perfect for structured garments like trousers, jackets, and skirts. This stretch provides mobility for sitting and bending while maintaining a crisp, tailored look and excellent shape retention. 4-Way stretch, which stretches both horizontally and vertically, offers maximum freedom of movement. It is predominantly reserved for high-activity performance wear and technical gear where complete, multi-directional elasticity is crucial, but it may sacrifice some of the fabric's overall structure and tailored appearance.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English 中文简体

中文简体