The Ultimate Guide to Mechanical Stretch Fabric: Technology, Applications, and Selection

2026-01-08

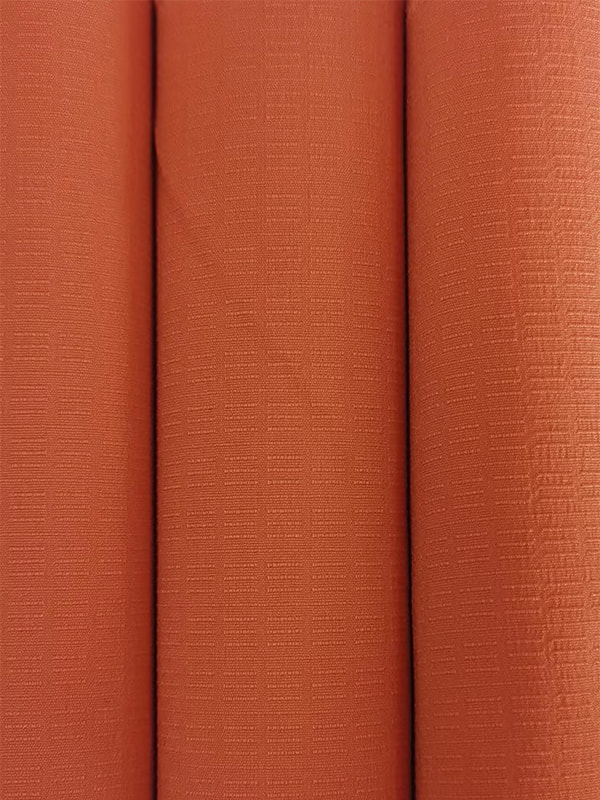

In the dynamic world of textiles, innovation is constant. Among the most significant advancements is the development of mechanical stretch fabric. Unlike elastane-blended materials, these fabrics achieve flexibility through their unique physical structure and weaving techniques, offering durability and consistent performance. This comprehensive guide delves into the technology behind these fabrics, their diverse applications, and key considerations for selection, highlighting why they are a cornerstone of modern textile engineering.

Understanding Mechanical Stretch Technology

Mechanical stretch, also known as structural or inherent stretch, refers to fabrics that gain their elasticity purely from the construction of the yarn or the weave/knit pattern, without relying on elastic fibers like spandex. This fundamental difference creates distinct advantages in terms of longevity, recovery, and comfort.

Core Mechanisms of Action

The stretch properties are engineered through several sophisticated methods:

- Yarn Construction: Using high-twist yarns (like crepe) or coiled, spring-like yarns that expand and contract.

- Weave Structure: Employing specific weaves such as satin or twill that allow threads to slide over each other.

- Knit Architecture: Utilizing knit loops that can easily deform and return to shape, inherent in many jersey and double-knit fabrics.

Mechanical Stretch vs. Chemical (Elastane) Stretch

Choosing between mechanical and chemical stretch depends on the application's requirements. For instance, while elastane offers extreme elongation, mechanical stretch provides better recovery over time and higher heat resistance. The key differences are best illustrated in a direct comparison.

Mechanical stretch fabrics are preferred for applications requiring consistent performance under frequent washing, whereas elastane blends might be chosen for extreme, form-fitting athletic wear. Below is a detailed comparison:

| Feature | Mechanical Stretch Fabric | Elastane-Blended Fabric |

|---|---|---|

| Stretch Mechanism | Physical structure of yarn or weave | Integrated synthetic elastic fibers |

| Long-Term Recovery | Excellent; maintains shape over many cycles | Can degrade with heat and time |

| Heat & Chemical Resistance | High; can withstand high-temperature processing | Moderate; fibers can be damaged by heat/chlorine |

| Typical Feel & Drape | Often more natural, like traditional fabrics | Can have a synthetic feel, very clingy |

| Primary Applications | Tailored apparel, durable workwear, home textiles | Activewear, swimwear, tight-fitting fashion |

Primary Applications Across Industries

The versatility of mechanical stretch fabric makes it indispensable across multiple sectors. Its ability to provide comfort, freedom of movement, and resilience without compromising the fabric's core character is highly valued.

Apparel and Fashion

In fashion, these fabrics bridge the gap between style and comfort. A common inquiry from designers is for mechanical stretch fabric for tailored suits, as it allows for sharp silhouettes that move with the wearer. Similarly, the demand for durable mechanical stretch workwear fabrics is rising in sectors requiring both safety and mobility, offering superior abrasion resistance compared to some elastic blends.

- Tailored Garments: Suits, blazers, and trousers that retain shape.

- Premium Casual Wear: Chinos, denim, and skirts with enhanced comfort.

- Durable Uniforms: For hospitality, healthcare, and industrial sectors.

Home and Technical Textiles

Beyond apparel, these fabrics bring functionality to other domains. Breathable mechanical stretch fabric for outdoor gear is crucial for performance jackets and hiking apparel, where moisture management and freedom of movement are paramount. In interior design, mechanical stretch upholstery fabric solutions are chosen for furniture that must withstand constant use while maintaining its fitted appearance, offering better longevity than non-stretch alternatives. Furthermore, innovations like high-recovery mechanical stretch fabric for athletic wear are finding their place in segments where durability against repeated stress is key.

How to Choose the Right Mechanical Stretch Fabric

Selecting the appropriate fabric requires a careful analysis of technical specifications and end-use needs.

Key Performance Parameters

Evaluating these parameters ensures the fabric will perform as expected.

- Stretch and Recovery Percentage: Measures how far the fabric stretches and its ability to return to original dimensions.

- Durability (Abrasion Resistance): Critical for workwear and upholstery; look for high Martindale or Wyzenbeek test results.

- Breathability and Moisture Wicking: Essential for active and outdoor applications.

- Weight and Drape: Determines the fabric's hand feel and suitability for different garment types.

Fiber Content and Construction Impact

The choice of base fiber (cotton, polyester, nylon, wool) dramatically affects the fabric's final properties. For example, a polyester-based mechanical stretch will offer great strength and wrinkle resistance, while a cotton-based one provides superior breathability and a natural feel. The construction—whether woven or knitted—also defines the stretch direction (bi-directional or four-way) and the fabric's overall character.

Innovations and Future Trends

The future of mechanical stretch fabric is geared towards smarter and more sustainable solutions. Advances in yarn engineering are creating stretch with even higher recovery rates. There is a significant industry push to develop eco-friendly versions, using recycled fibers or optimizing production to reduce water and energy consumption. The integration of smart textiles, where stretch fabrics incorporate sensors for health monitoring, is also an emerging frontier, particularly in the performance and medical fields.

Expert Manufacturing with a Global Vision

Producing high-quality mechanical stretch fabric requires integrated expertise from fiber to finished cloth. Suzhou Redcolor International Trading Co., Ltd. exemplifies this approach. With subsidiaries like Suzhou LJC Textile Co., Ltd. and Wujiang Jiabaokang Textile Co., Ltd., the company controls a vertically integrated process encompassing spinning, texturing, weaving, and trade. Operating from production bases in Wujiang, Suzhou and Siyang, Suqian, with an annual output of approximately 60 million meters, the company leverages this scale and control to ensure precision in creating advanced textiles. The mechanical stretch fabric and other shell & lining materials produced are engineered for global markets, including the United States, Europe, and Southeast Asia. Adhering to a philosophy of high-quality and better products, Suzhou Redcolor is dedicated to serving every customer's need for reliable, innovative, and performance-driven textile solutions.

Frequently Asked Questions (FAQ)

1. What is the main advantage of mechanical stretch over spandex stretch?

The primary advantage is superior durability and recovery over time. Mechanical stretch fabrics are less prone to losing their elasticity from exposure to heat, chlorine, or repeated washing, making them ideal for garments and applications that require long-term shape retention.

2. Can mechanical stretch fabric be used for tight-fitting athletic clothing?

While it can be used, its stretch range is generally more moderate than high-elastane fabrics. It is excellent for athletic wear where high-recovery mechanical stretch fabric for athletic wear is needed—such as in training pants or jackets—that prioritize durability and consistent performance over extreme, second-skin compression.

3. How do I care for garments made from mechanical stretch fabric?

Care is often simpler than for elastane blends. Most can withstand higher washing temperatures. However, always check the specific care label. Avoiding excessive heat in dryers is still recommended to preserve the fabric's lifespan, though they are generally more heat-resistant.

4. Is mechanical stretch fabric more expensive?

The cost can vary based on the base fiber (e.g., wool vs. polyester) and construction complexity. While sometimes having a higher initial cost than basic fabrics, it often provides better value due to its longevity and performance, especially for durable mechanical stretch workwear fabrics or mechanical stretch upholstery fabric solutions.

5. How sustainable are mechanical stretch fabrics?

Sustainability depends on the base materials and production processes. They have an advantage as they typically avoid synthetic elastane, which is derived from non-renewable resources and can be harder to recycle. Many manufacturers are now offering versions made with recycled fibers and employing eco-friendly dyeing and finishing techniques, enhancing their sustainability profile.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English 中文简体

中文简体