Twill Stretch Woven Fabric vs. Plain Weave Stretch Fabric: A Technical Guide for Manufacturers

2026-01-14

When selecting a stretch woven fabric for a product line, the choice between a twill stretch woven fabric and a plain weave variant is a critical technical decision. This choice impacts not only aesthetics and hand feel but also durability, performance, and end-use application. As a vertically integrated manufacturer with extensive production capabilities, Suzhou Redcolor International Trading Co., Ltd. understands these nuances at an engineering level. This guide provides a detailed, objective comparison to empower B2B buyers, designers, and product developers in making informed sourcing decisions.

Understanding the Core: Weave Structure Fundamentals

Before diving into the comparison, it's essential to understand the architectural blueprint of each fabric: the weave structure. This foundational element dictates all subsequent properties.

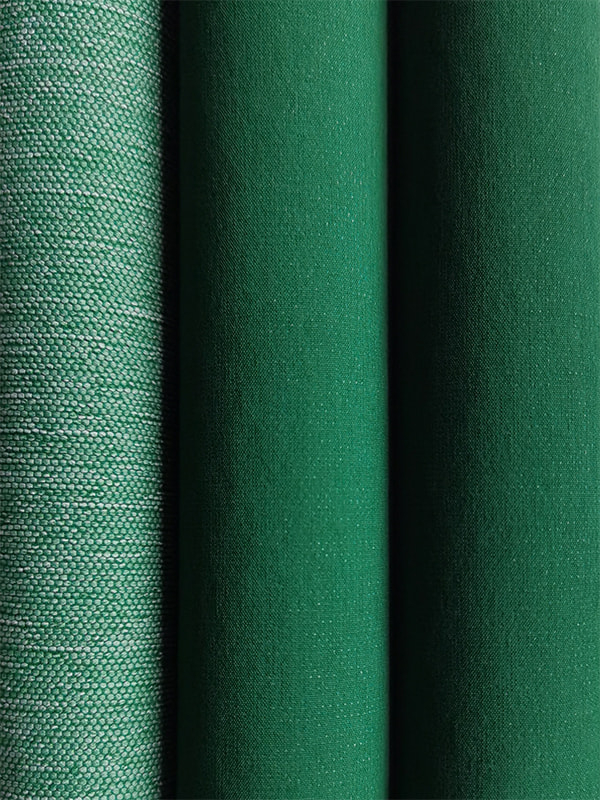

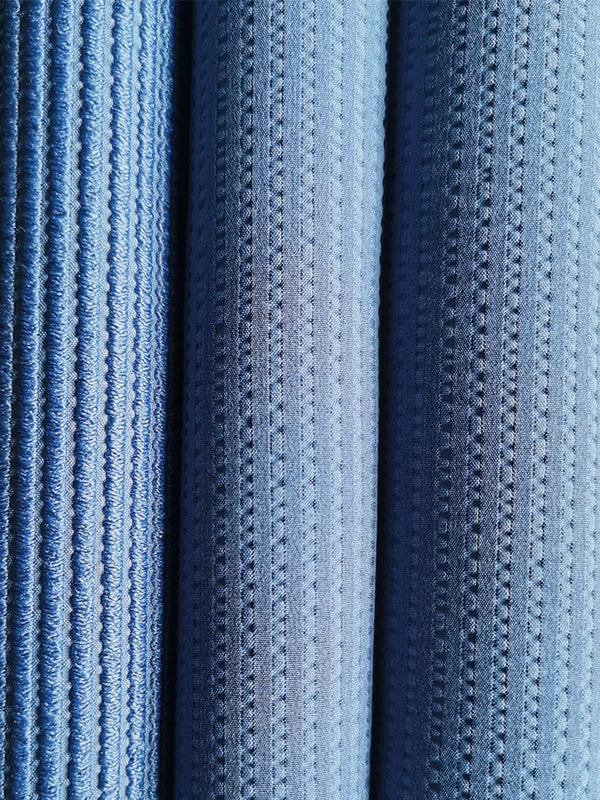

Plain Weave Structure

Plain weave is the simplest and most common interlacing pattern. The weft yarn passes alternately over and under each warp yarn in a consistent 1x1 sequence. This creates a uniform, flat surface with high yarn intersection frequency, resulting in inherent stability.

Twill Weave Structure

Twill weave is characterized by a diagonal rib pattern. This is achieved by having the weft yarn pass over one or more warp yarns, then under two or more, with this sequence offset in subsequent rows to create the distinctive diagonal line. Common patterns include 2/1 or 3/1 twill. This structure produces a fabric with a technical face and back.

Head-to-Head Technical Comparison

The structural differences manifest in distinct performance profiles. Below is a detailed analysis across key parameters crucial for industrial procurement.

Durability and Abrasion Resistance

Durability is a primary concern for manufacturers targeting markets for workwear, uniforms, or heavy-use apparel. The comparison reveals a clear advantage for one structure in this domain.

Twill stretch woven fabric generally exhibits superior durability and abrasion resistance. The twill weave's diagonal structure allows for a higher thread count (more yarns per square inch) as the yarns can be packed more densely. Furthermore, the float (where a yarn goes over multiple opposing yarns) distributes friction and stress across a broader area of the yarn, reducing concentrated wear. This makes it an excellent candidate for producing durable stretch twill for work uniforms that must withstand rigorous daily use.

In contrast, plain weave stretch fabric, while strong, has a higher frequency of yarn crossover points. These intersections are potential stress concentration points, making the fabric more susceptible to abrasion at these specific locations over prolonged use.

| Property | Twill Stretch Woven Fabric | Plain Weave Stretch Fabric |

| Abrasion Resistance | Superior. Floats distribute friction. | Good, but stress concentrates at交叉 points. |

| Yarn Density Potential | Higher (more dense). | Lower due to simple 1x1 structure. |

| Typical Application | Workwear, tactical gear, durable outerwear. | Lightweight shirts, blouses, linings. |

Drape, Softness, and Hand Feel

The aesthetic and tactile qualities of a fabric directly influence consumer perception and comfort. This is where the intrinsic character of each weave shines.

Twill stretch woven fabric offers a superior, more luxurious drape and a noticeably softer hand feel. The longer floats in the twill structure create fewer "crimp" points in the yarns, allowing them to remain more flexible and fluid. This inherent softness is why twill is often the preferred base for soft twill stretch fabric for dresses and high-end tailored trousers, where fluid movement and a comfortable, premium feel are paramount.

Plain weave fabric tends to have a crisper, more structured hand. The frequent yarn interlacings create a firmer, sometimes slightly stiffer fabric body. While it can be made soft with fine yarns and finishing, it typically lacks the inherent fluidity of a twill.

| Property | Twill Stretch Woven Fabric | Plain Weave Stretch Fabric |

| Drape & Fluidity | Excellent, fluid drape. | Crisper, more structured drape. |

| Hand Feel | Softer, smoother surface. | Firmer, can be crisp or papery. |

| Typical Application | Draped garments, soft tailoring, skirts. | Structured shirts, poplin blouses, canvas. |

Wrinkle Resistance and Recovery

Performance in wear and care is a key selling point. The ability to resist and recover from wrinkles is largely a function of the weave's mechanical grip on the yarns.

Twill stretch woven fabric often demonstrates better wrinkle recovery. The longer floats allow yarns to shift and return to position more easily after bending or crushing. This property is a significant advantage for travel clothing or business attire that needs to maintain a neat appearance. The development of wrinkle resistant stretch twill fabric leverages this inherent characteristic, often enhanced by fiber blends (like polyester-cotton) and chemical finishes.

Plain weave fabric, with its tight yarn interlacings, locks yarns in place more rigidly. When creased, these sharp bends can become more permanently set, requiring higher heat or steam to remove.

Production Complexity and Cost Implications

From a manufacturing and sourcing perspective, understanding production nuances is vital for cost planning and lead time management.

Plain weave is mechanically simpler and faster to produce on a loom, often resulting in a lower cost per meter for equivalent base materials. It is the most efficient weave to produce.

Twill weave requires more precise loom setup and is generally produced at a slightly slower rate due to its more complex harness movement. This can contribute to a marginally higher base cost. However, for mills like those under Suzhou Redcolor, which integrate spinning, texturing, and weaving, this complexity is managed efficiently within the vertical supply chain, optimizing both quality and cost for large-scale orders, such as those needed for producing consistent bulk twill stretch fabric for wholesale.

Moisture Management and Breathability

For activewear or garments for variable climates, a fabric's interaction with moisture is critical. Recent industry focus has intensified on this functional aspect.

The comparison here is nuanced and heavily dependent on yarn type and finish. Generally, a looser plain weave can be very breathable. However, the dense construction of a high-quality twill can be engineered to excel in moisture-wicking. The capillary action along the yarn floats in a twill can effectively transport moisture. This engineering makes specific moisture wicking stretch twill fabric a top choice for performance polos and active shirts.

According to the latest report by the International Textile Manufacturers Federation (ITMF), there is a growing market demand for multi-functional woven fabrics that combine durability with climate-regulation properties. Innovations in yarn spinning (like hybrid tech-fibers) and finishing technologies are being increasingly applied to traditional weaves like twill to enhance their performance profile beyond basic aesthetics.

Source: International Textile Manufacturers Federation (ITMF) - State of Trade & Industry Reports - https://www.itmf.org/publications/state-of-trade-industry-reports

Making the Strategic Choice: Application-Based Guidance

The optimal choice is dictated by the end-use. Here’s a technical selection framework:

- Choose Twill Stretch Woven Fabric for:

- Garments requiring durability and abrasion resistance (e.g., workwear, military uniforms, rugged outerwear).

- Applications where a soft hand, superior drape, and a premium feel are critical (e.g., high-end chinos, dresses, tailored jackets).

- Products that benefit from inherent wrinkle recovery (e.g., travel clothing, business casual pants).

- Engineered performance wear where moisture management is built into a durable fabric structure.

- Choose Plain Weave Stretch Fabric for:

- Lightweight, structured garments where a crisp hand is desired (e.g., dress shirts, blouses, some types of linings).

- Applications where cost-efficiency on high-volume, simpler constructions is a primary driver.

- Fabrics where maximum breathability in a simple, open construction is key.

Expert Insights from Integrated Manufacturing

At Suzhou Redcolor International Trading Co., Ltd., our vertical integration—from spinning and texturing to weaving and finishing—provides a unique vantage point. Controlling the entire process allows for precise engineering of both twill stretch woven fabric and plain weave variants. For instance, we can optimize the stretch yarn (like a core-spun spandex) integration during the texturing and warping stages to ensure uniform recovery and consistency across 60 million meters of annual production. This level of control is essential for B2B partners who require not just a fabric, but a reliably performing material component for their global product lines sold to markets like the United States, Europe, and Southeast Asia. Our commitment is to leverage this integrated capability to produce the right fabric for the right application, adhering strictly to the principle of high-quality, fit-for-purpose textiles.

FAQ: Technical Questions on Stretch Woven Fabrics

1. Is twill stretch fabric always heavier than plain weave stretch fabric?

Not necessarily. While twill can support higher densities, the final weight (grams per square meter, GSM) is primarily determined by yarn thickness (count) and density (thread count). A fine-yarn, lightweight twill can be similar in weight to a plain weave. The key difference is the *hand* and *drape* at comparable weights.

2. Which weave has better dimensional stability with stretch yarns?

Both can be engineered for excellent stability. Plain weave may have a slight edge in maximum warp/weft stability due to its tight interlocking. However, modern finishing processes (like compacting and heat-setting) on twill fabrics can achieve outstanding dimensional stability, making both suitable for precision garment cutting.

3. Can plain weave be made as soft as twill?

It can be softened through mechanical (brushing, sanding) and chemical (enzyme washes, softeners) finishing. However, it will not replicate the distinctive, fluid drape of a twill. The softness in plain weave is often a surface treatment, while in twill it is a structural characteristic.

4. For a cost-sensitive uniform program, which is more economical?

Plain weave stretch fabric typically has a lower base cost due to faster production. It is an excellent choice for cost-sensitive programs where extreme durability is not the primary concern. For programs requiring higher durability that justifies a slightly higher cost, a durable stretch twill for work uniforms offers better long-term value.

5. How do I specify the right twill stretch fabric for my product?

Provide your supplier with detailed technical specifications: target GSM, composition (e.g., 65% Polyester / 33% Cotton / 2% Spandex), stretch and recovery percentage requirements, colorfastness standards, and intended end-use. An integrated manufacturer can then advise on the optimal yarn selection, weave density, and finishing process.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English 中文简体

中文简体